- Products

-

-

-

Categories

BG100

BG100LIGHT DUTY 2-BOLT CLAMP

BG170

BG170MEDIUM DUTY 2-BOLT PIPE CLAMP

BG50

BG50HEAVY DUTY 2-BOLT PIPE CLAMP

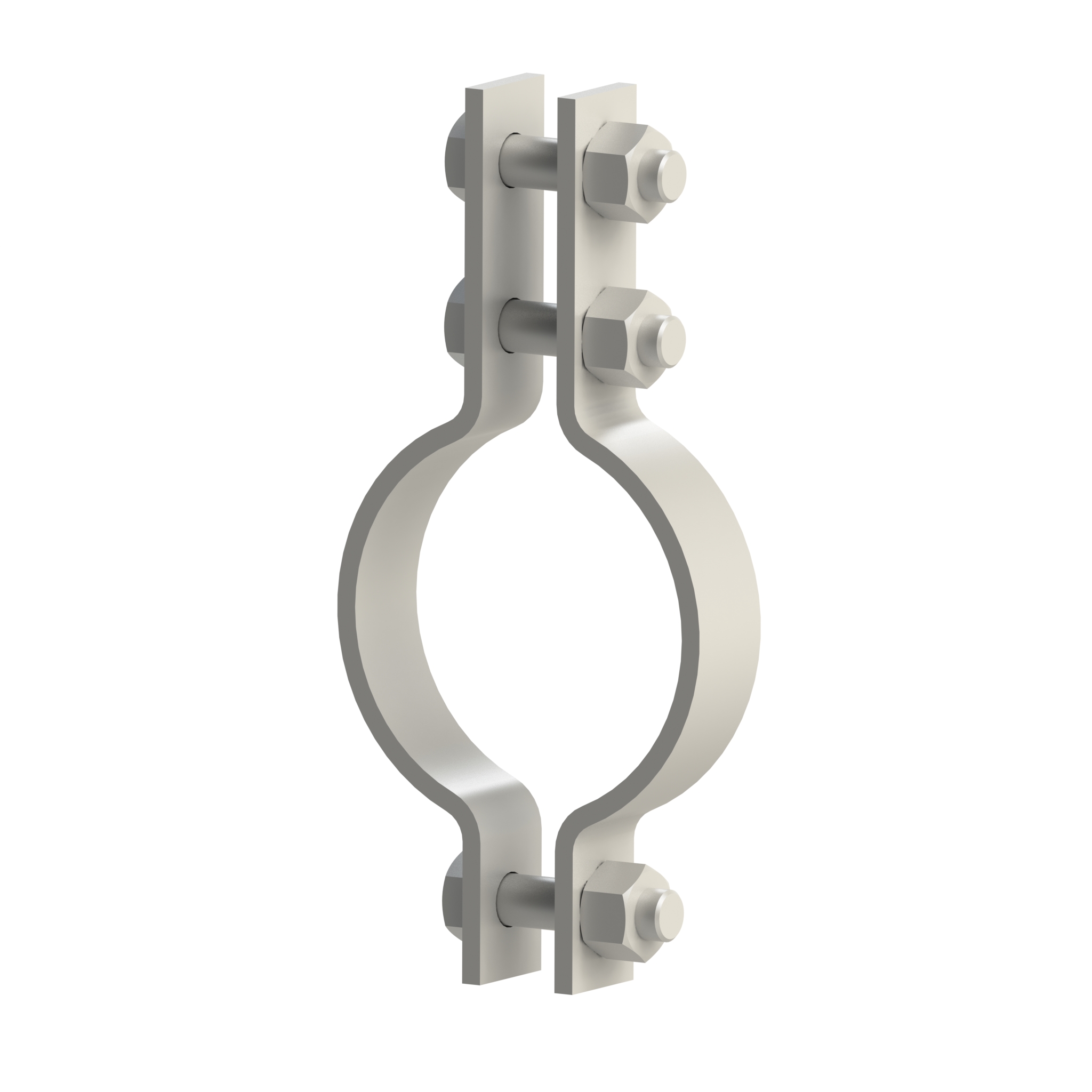

BG101

BG101LIGHT DUTY 3-BOLT PIPE CLAMP

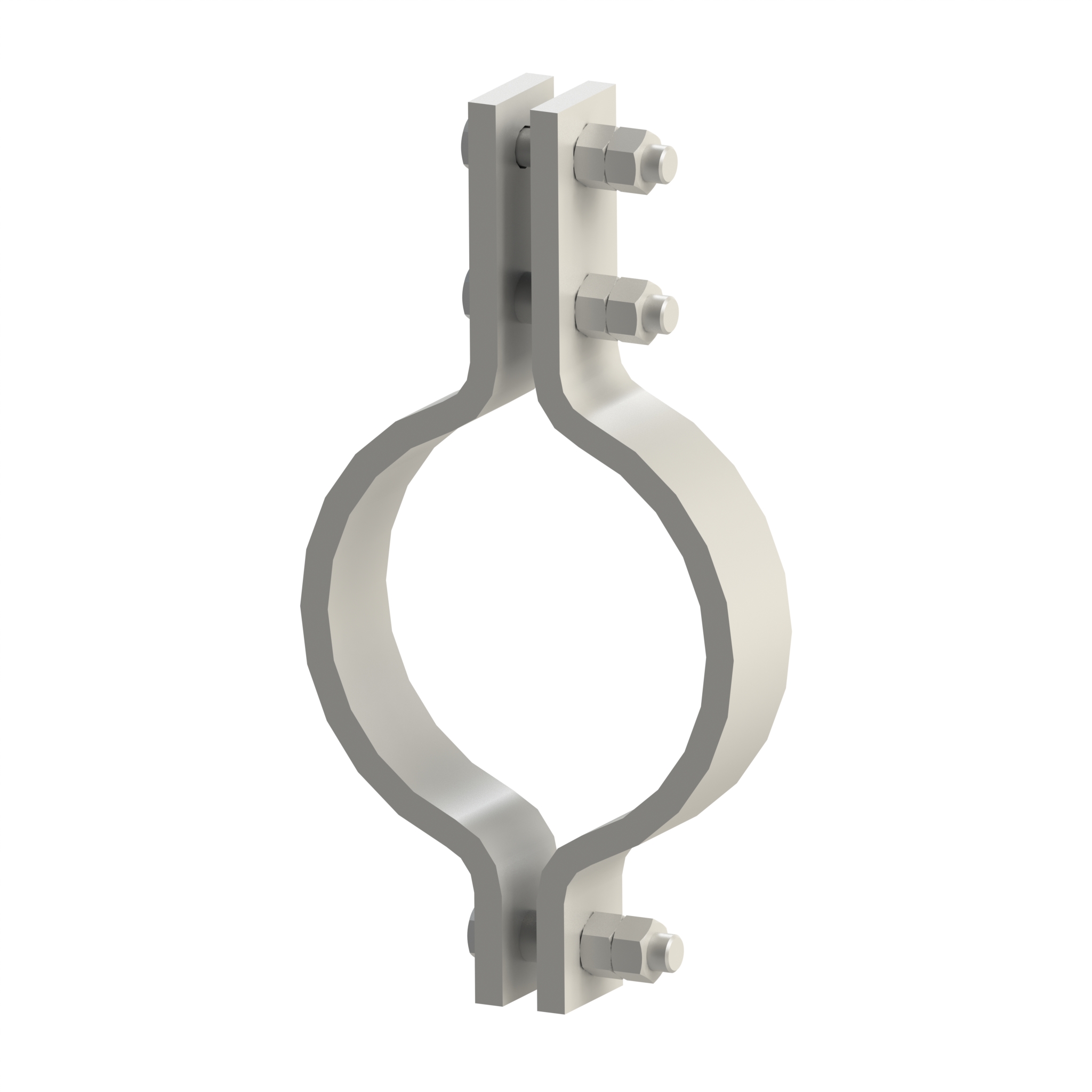

BG171

BG171MEDIUM DUTY 3-BOLT PIPE CLAMP FOR STEEL PIPE

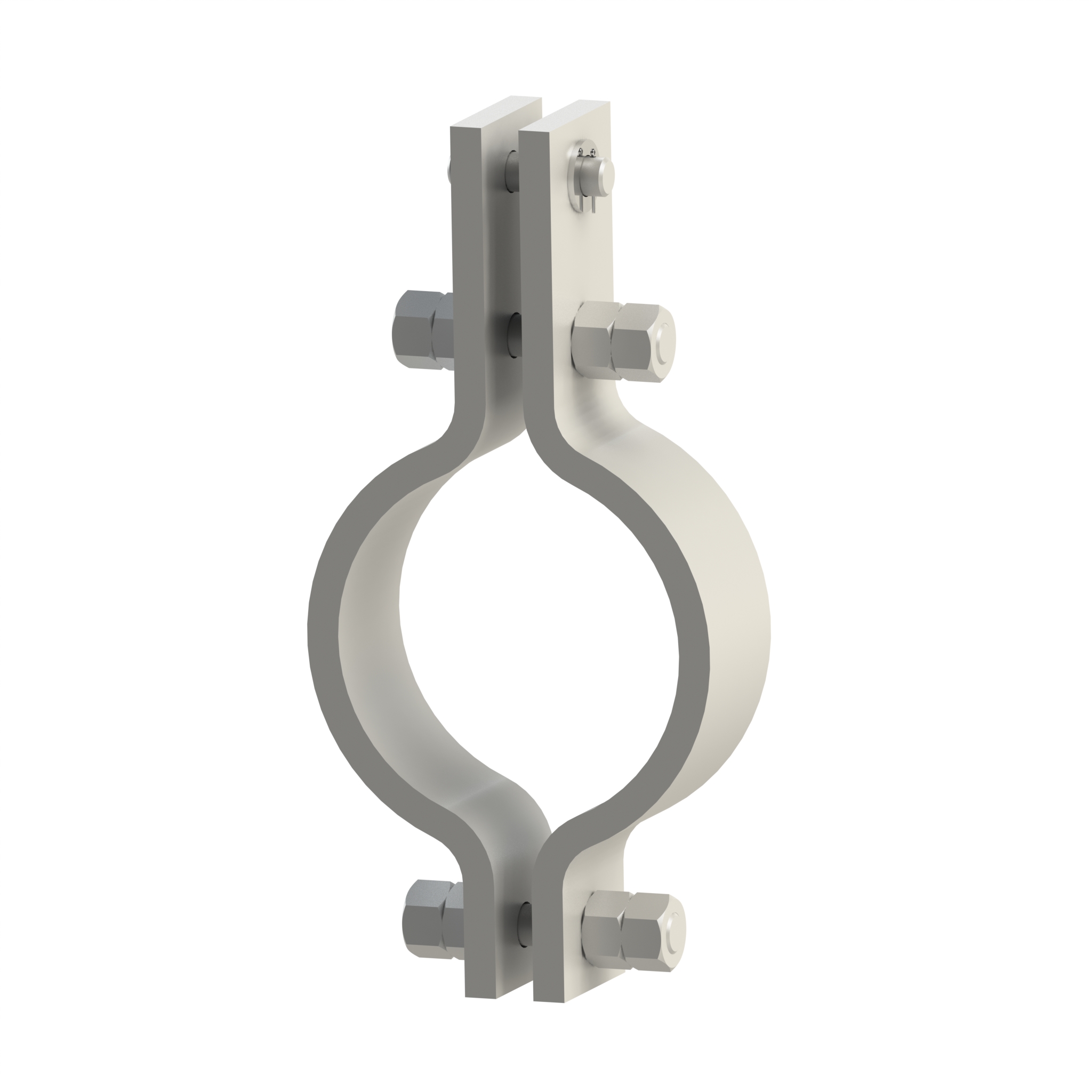

BG75

BG75HEAVY DUTY 3-BOLT PIPE CLAMP

BG172

BG172HIGH TEMPERATURE 3-BOLT PIPE CLAMP

BG173

BG173ALLOY PIPE CLAMP - VERY HIGH TEMPERATURE

BG140

BG140INSULATED 2-BOLT PIPE CLAMP

BG141

BG141INSULATED 2-BOLT PIPE CLAMP FOR CU/NI

BG145

BG145INSULATED 3-BOLT PIPE CLAMP

BG146

BG146INSULATED 3-BOLT PIPE CLAMP FOR CU/NI

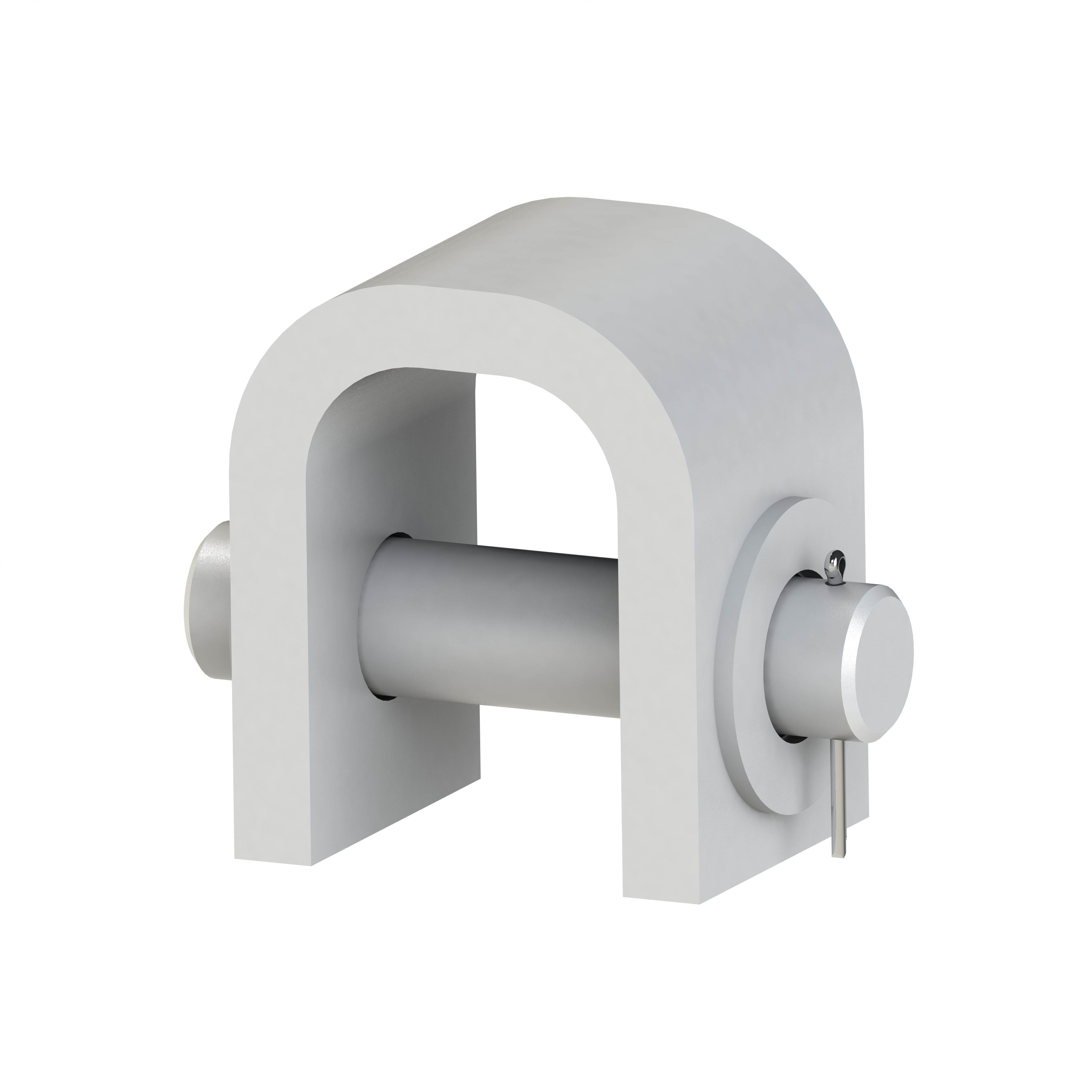

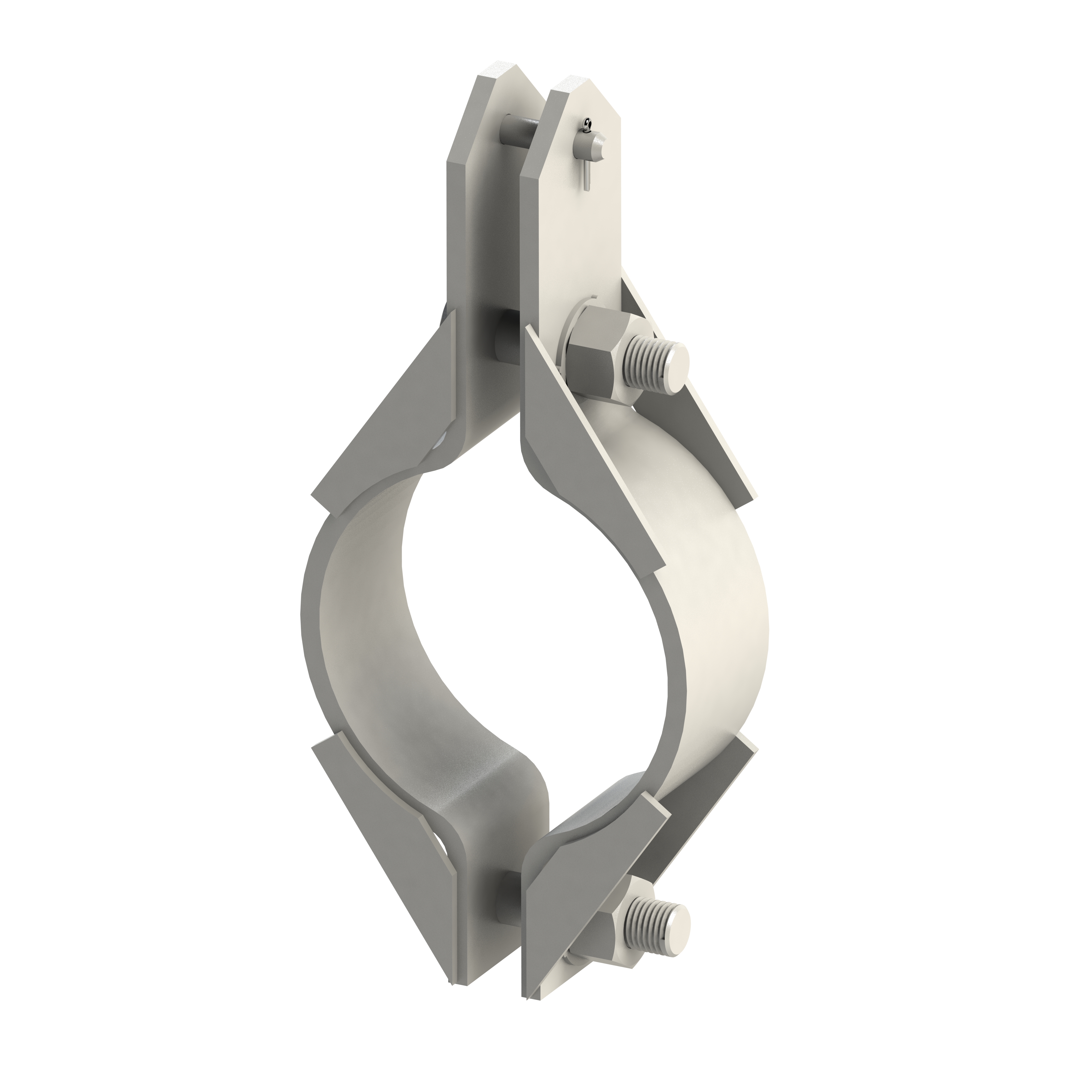

BG108

BG108CLEVIS CLAMP

BG222

BG222BEAM CLAMP

BG174

BG174RISER SUPPORT – STD TEMPERATURE

BG175

BG175RISER SUPPORT – HIGH TEMPERATURE

BG176

BG176ALLOY RISER SUPPORT - VERY HIGH TEMPERATURE

BG202

BG202ALLTHREAD ROD

BG209

BG209FORGED CLEVIS AND PIN

BG210

BG210FORGED TURNBUCKLE

BG204

BG204FORGED WELDLESS EYE NUT

BG215

BG215HEMISPHERICAL CUP

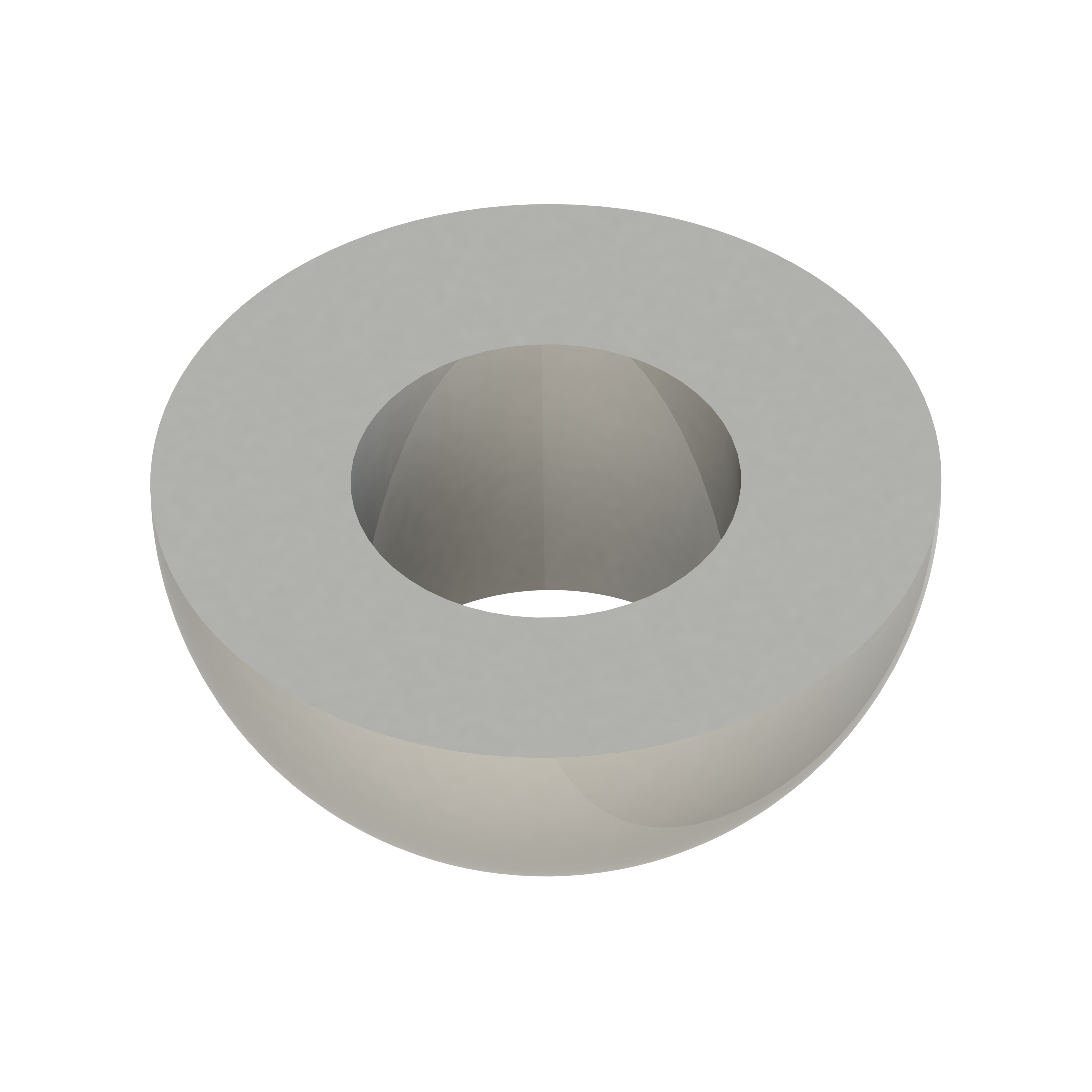

BG214

BG214HEMISPHERICAL WASHER

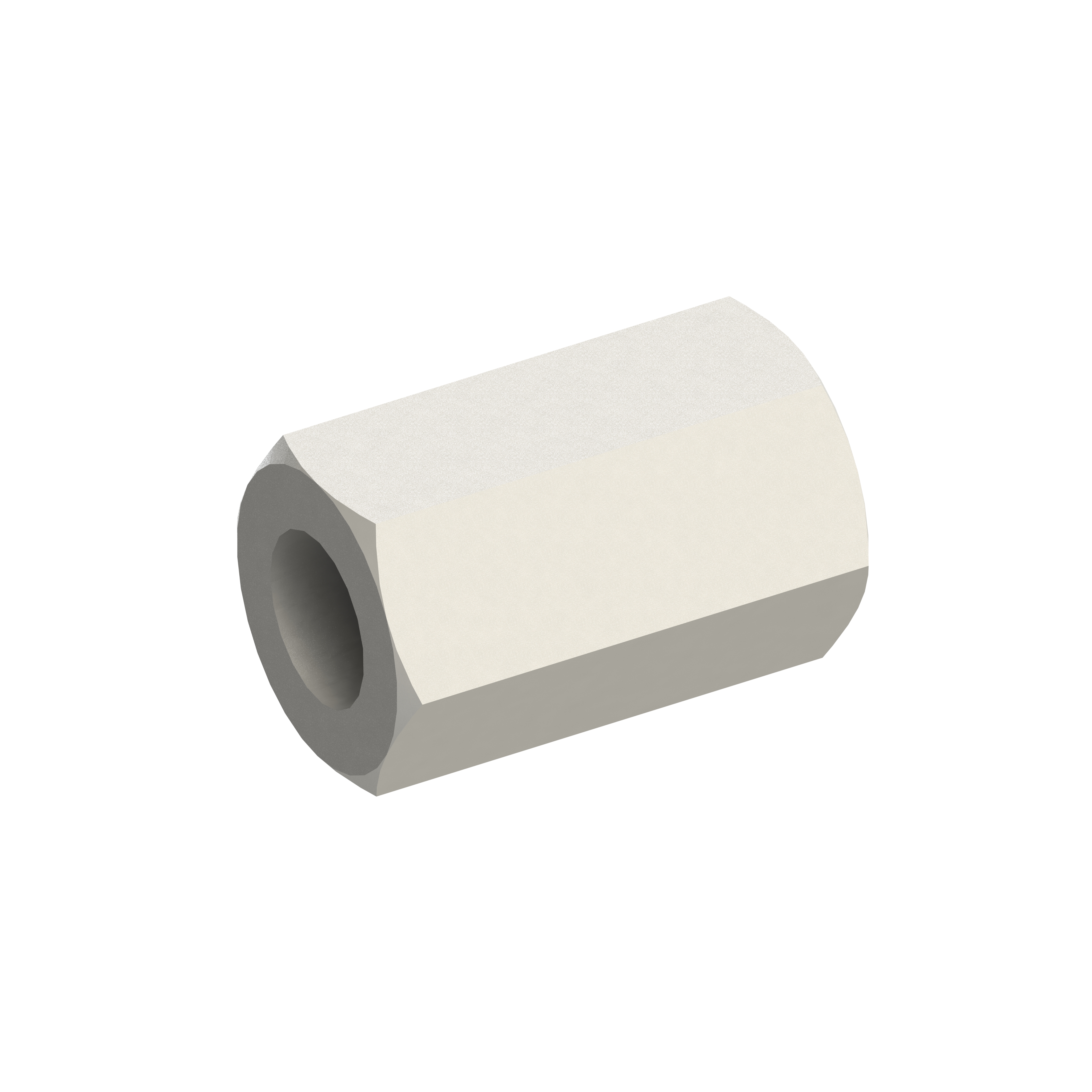

BG206

BG206HEXAGONAL CONNECTOR

BG216

BG216PIPE WELDING LUG

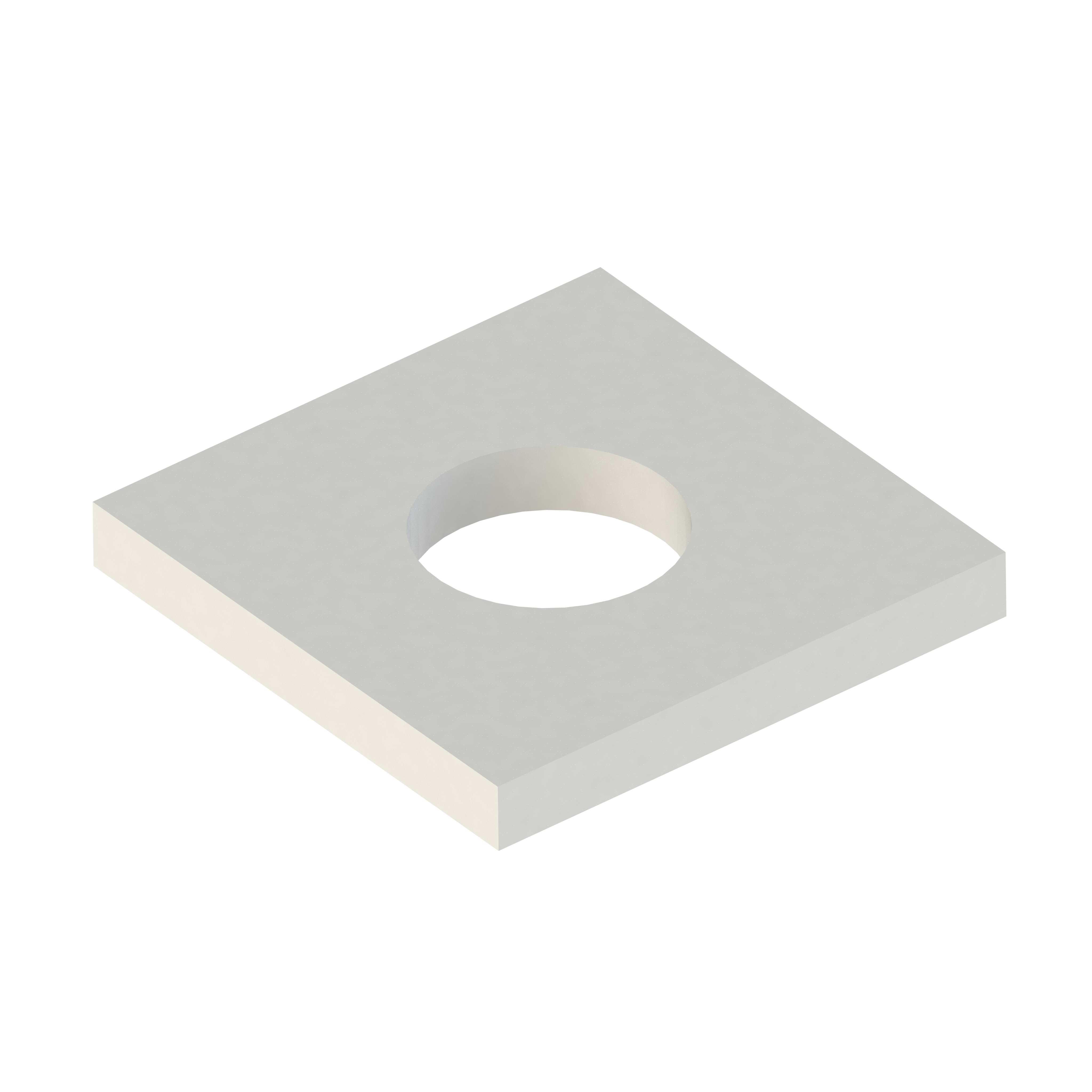

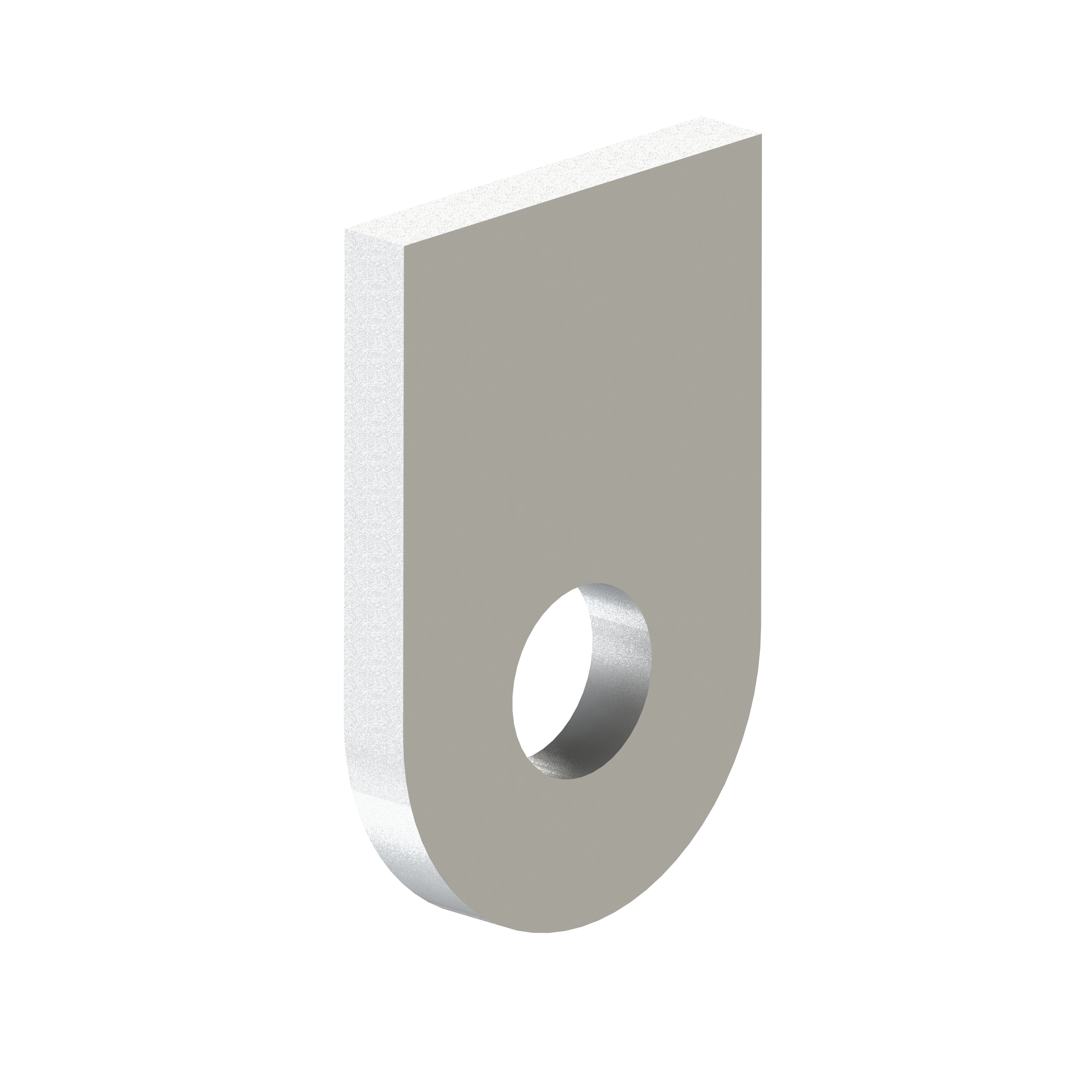

BG217

BG217PLATE WASHER

BG207

BG207SPADE NUT

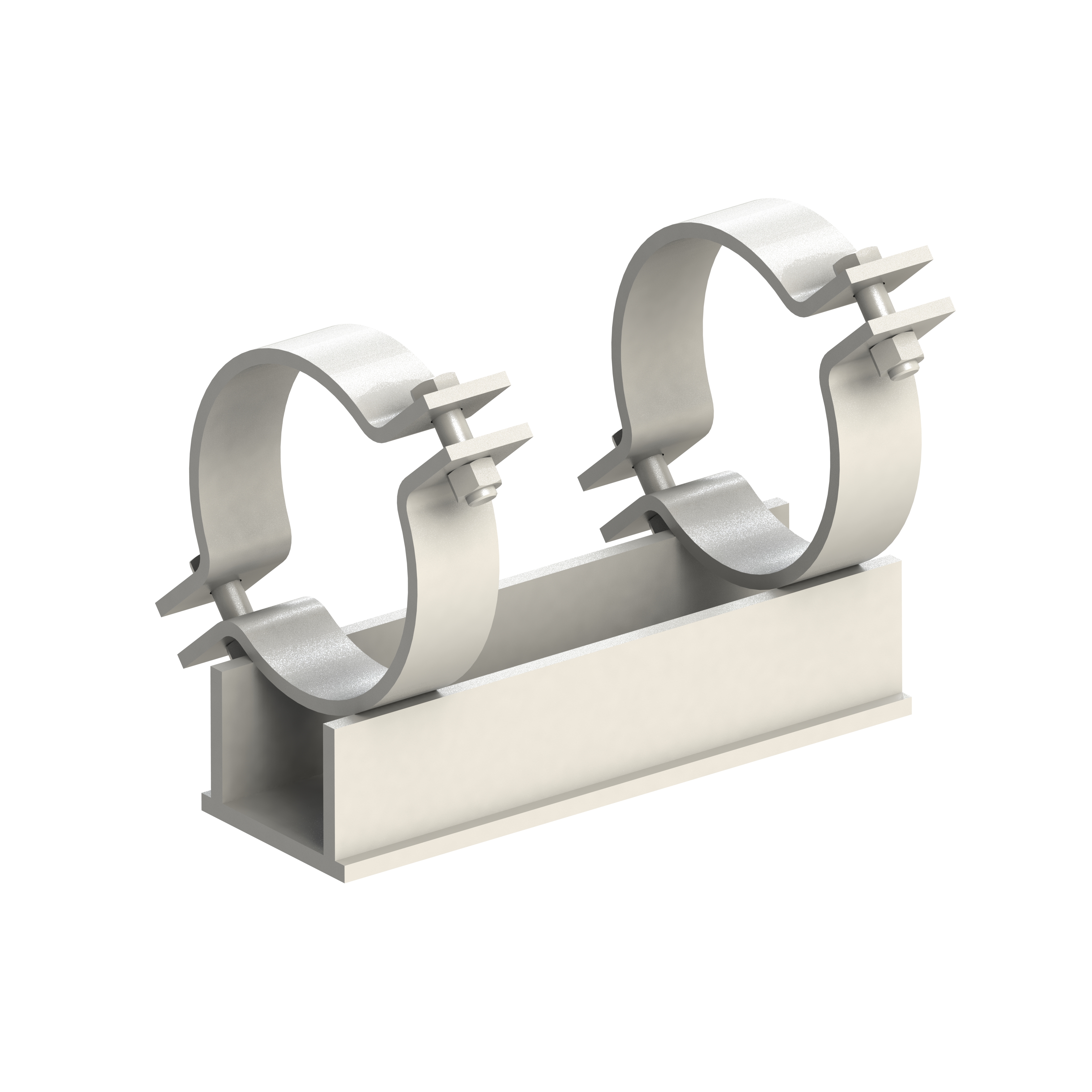

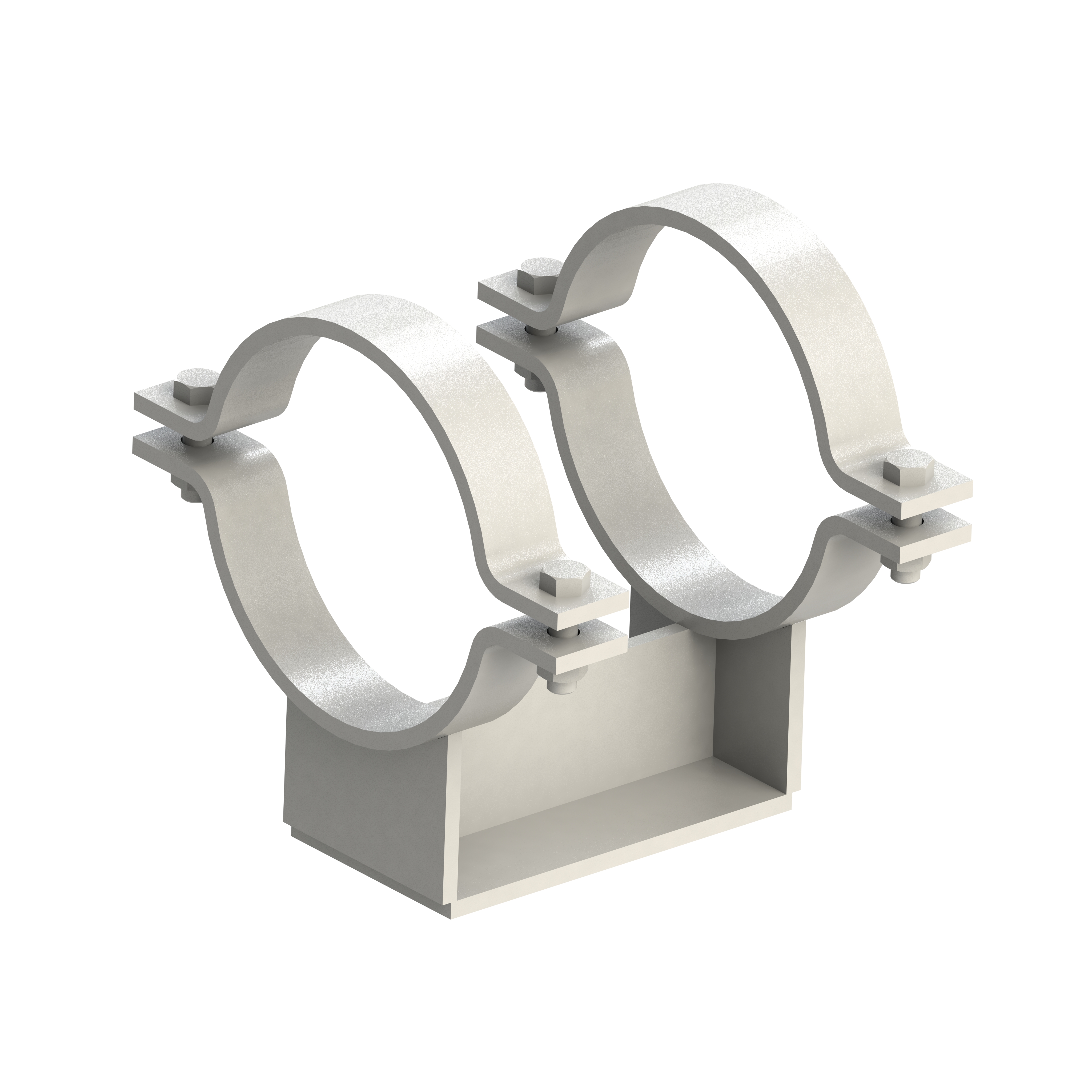

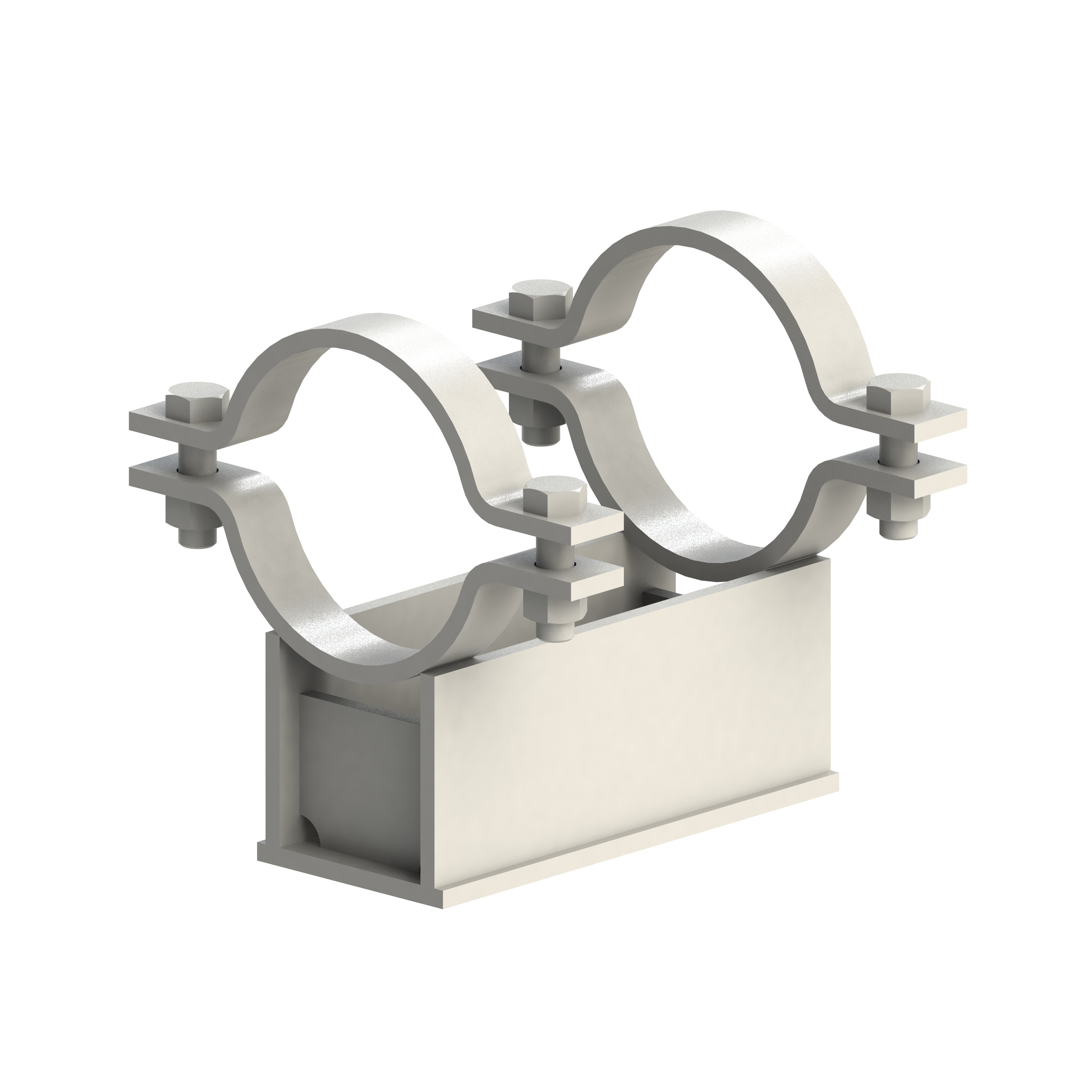

BG245

BG245STANDARD TRAPEZE

BG203

BG203THREADED DROP ROD – RH/LH

BG219

BG219WELDED BEAM ATTACHMENT

BG220

BG220WELDED BEAM ATTACHMENT (WITH LOAD PIN)

BG225

BG225WELDING LUG

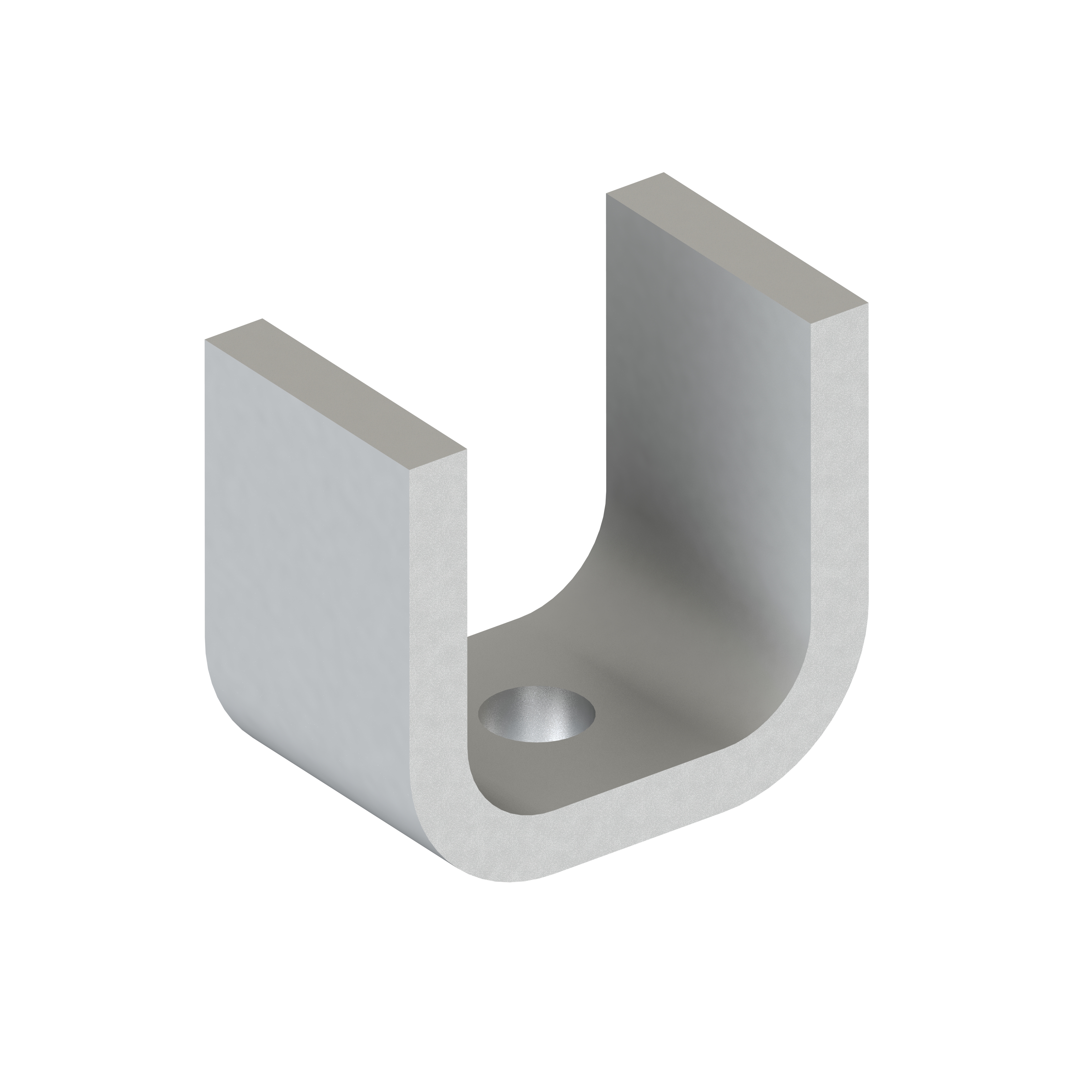

BG180

BG180U-BOLT GUIDE

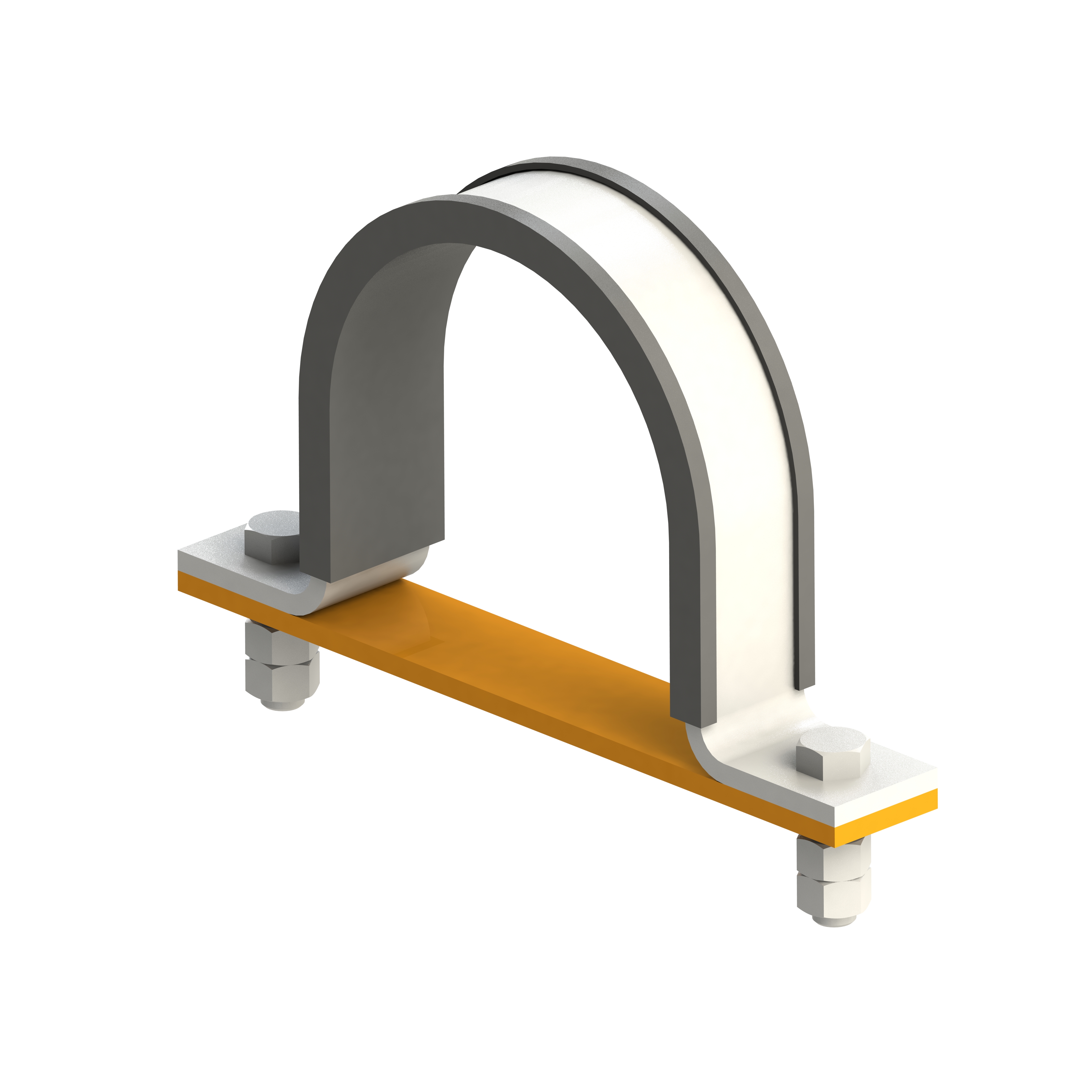

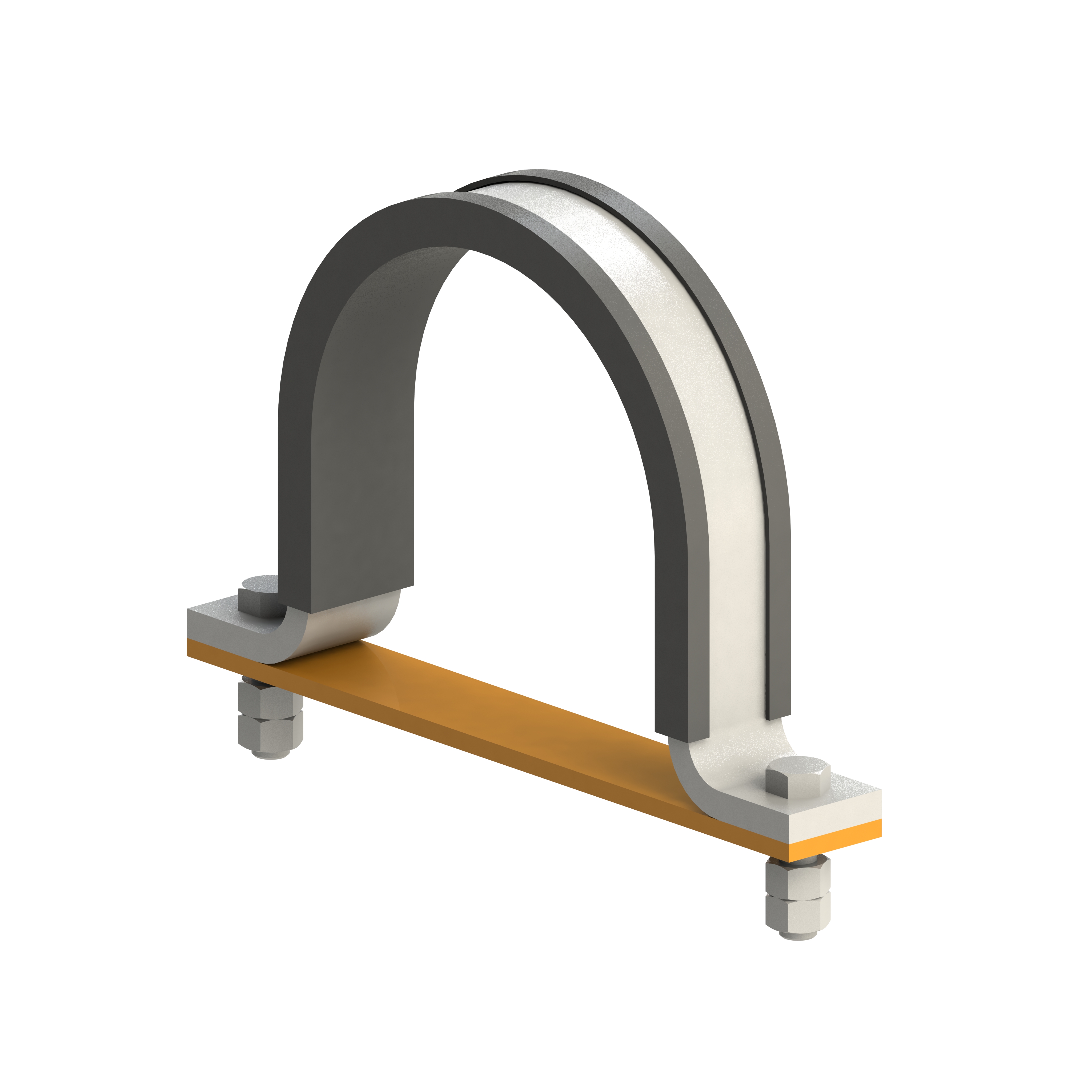

BG181

BG181U-BOLT CLAMP

BG150

BG150INSULATED U-BOLT CLAMP

BG152

BG152INSULATED U-BOLT GUIDE

BG154

BG154INSULATED U-BOLT GUIDE (WITH TEFLON)

BG190

BG190INSULATED U-BOLT CLAMP

BG192

BG192INSULATED U-BOLT GUIDE

BG151

BG151INSULATED U-BOLT CLAMP FOR CU/NI

BG153

BG153INSULATED U-BOLT GUIDE FOR CU/NI

For Cu/Ni Pipe BG155

BG155INSULATED U-BOLT GUIDE (WITH TEFLON)

For Cu/Ni Pipe BG177

BG177SADDLE GUIDE

BG178

BG178SADDLE CLAMP

BG160

BG160INSULATED PIPE SADDLE

BG161

BG161INSULATED PIPE SADDLE

BG162

BG162INSULATED PIPE SADDLE

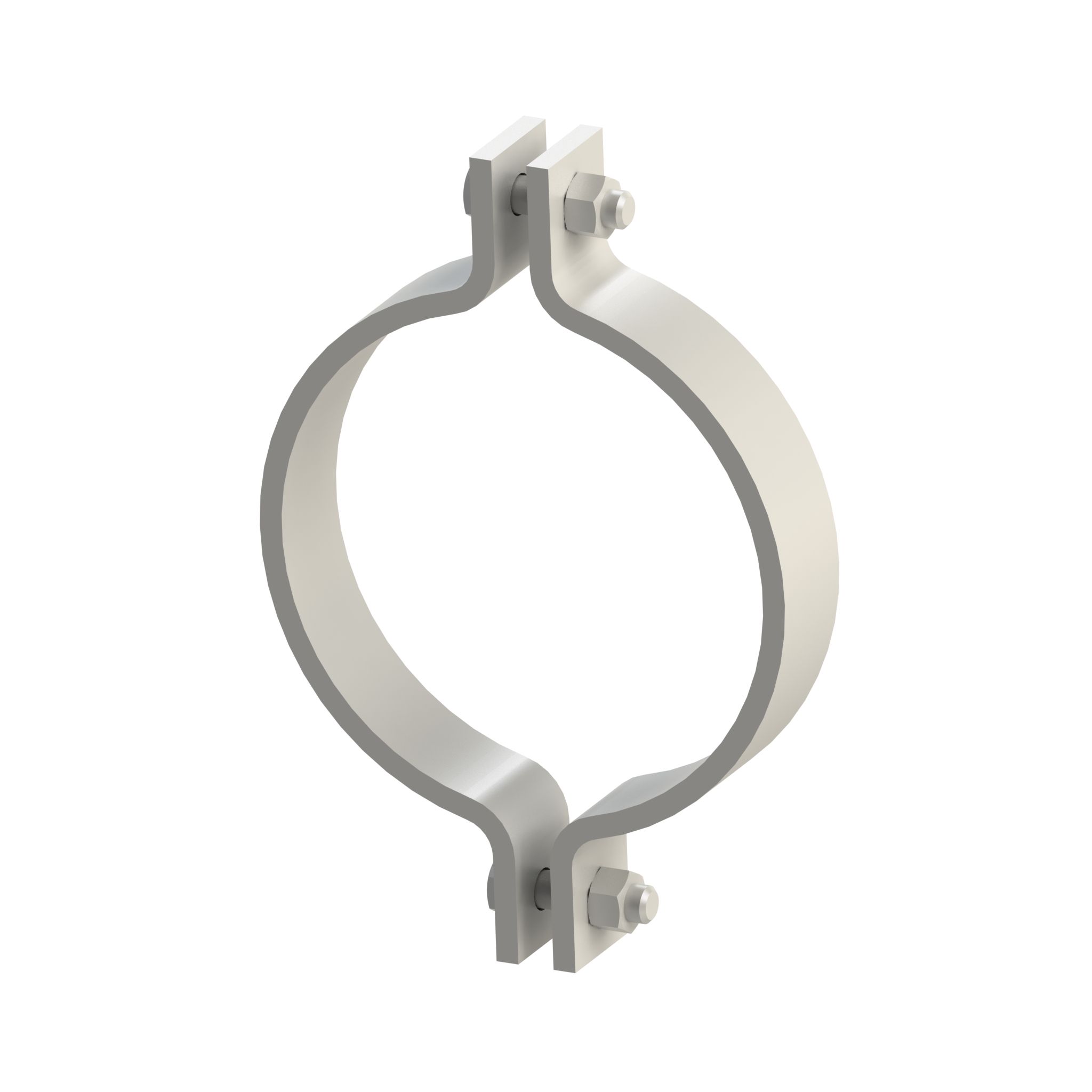

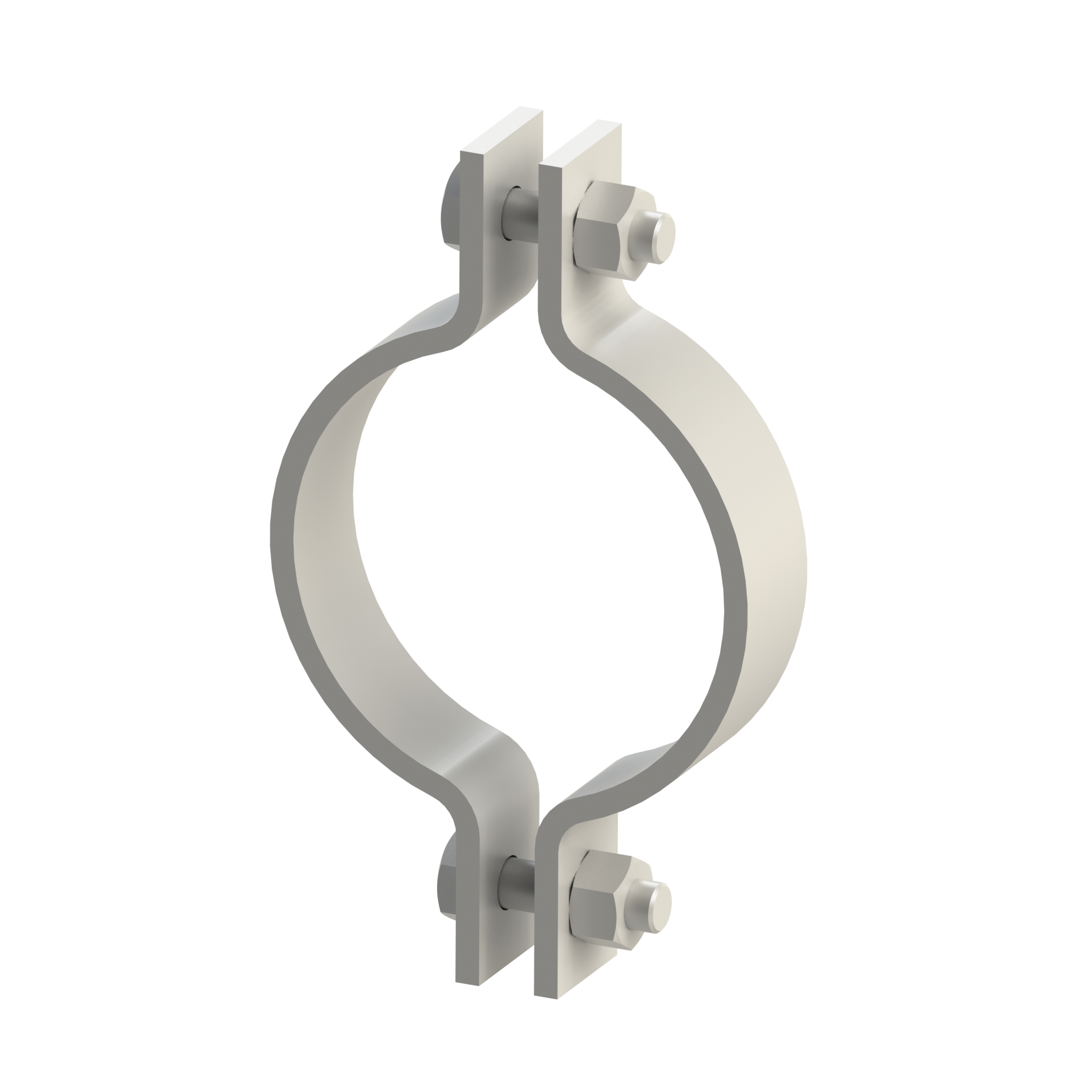

BG135-136

BG135-136ADJUSTABLE PIPE STANDS

BG515

BG515STANDARD CLAMPED PIPE SHOE

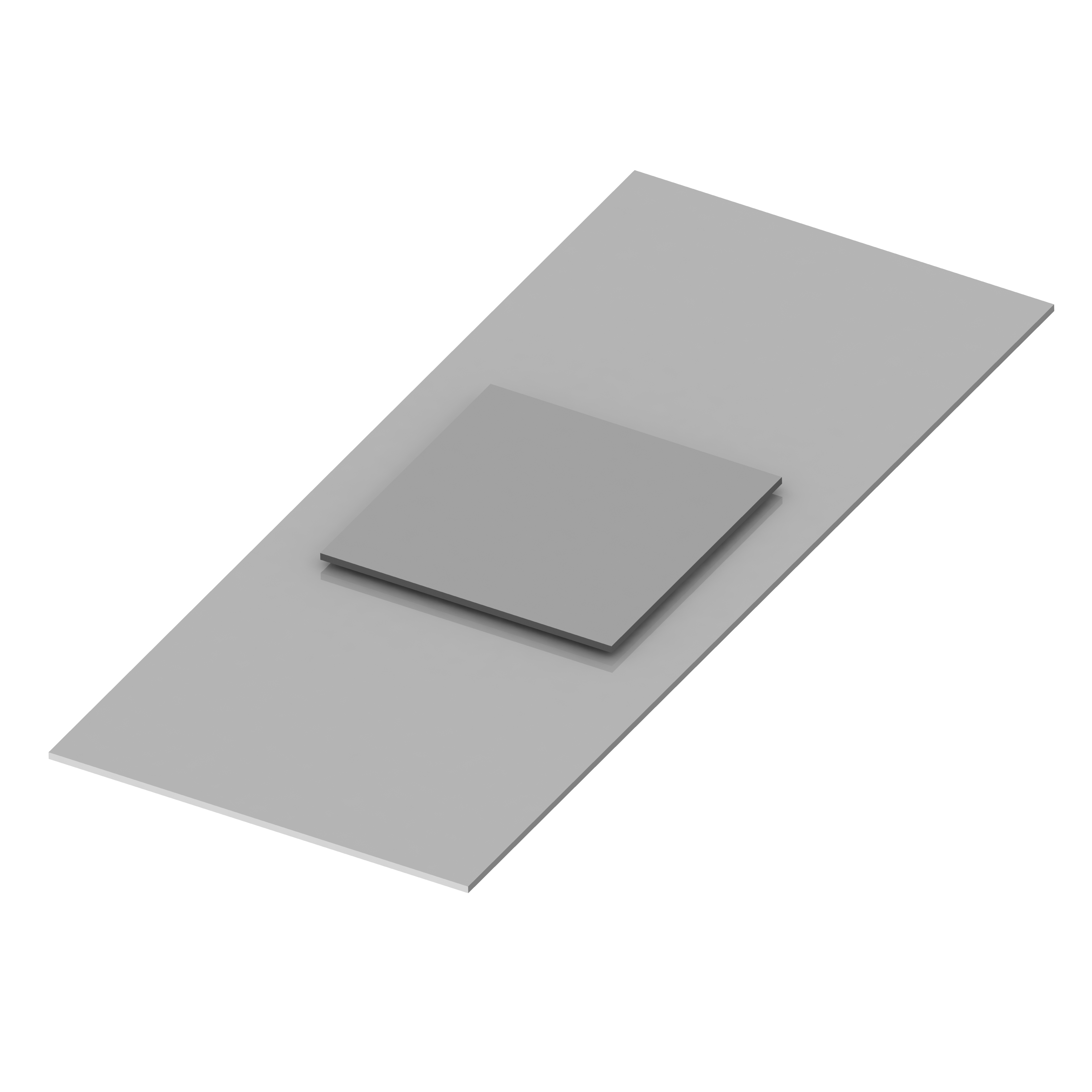

BG550

BG550SLIDE PLATES

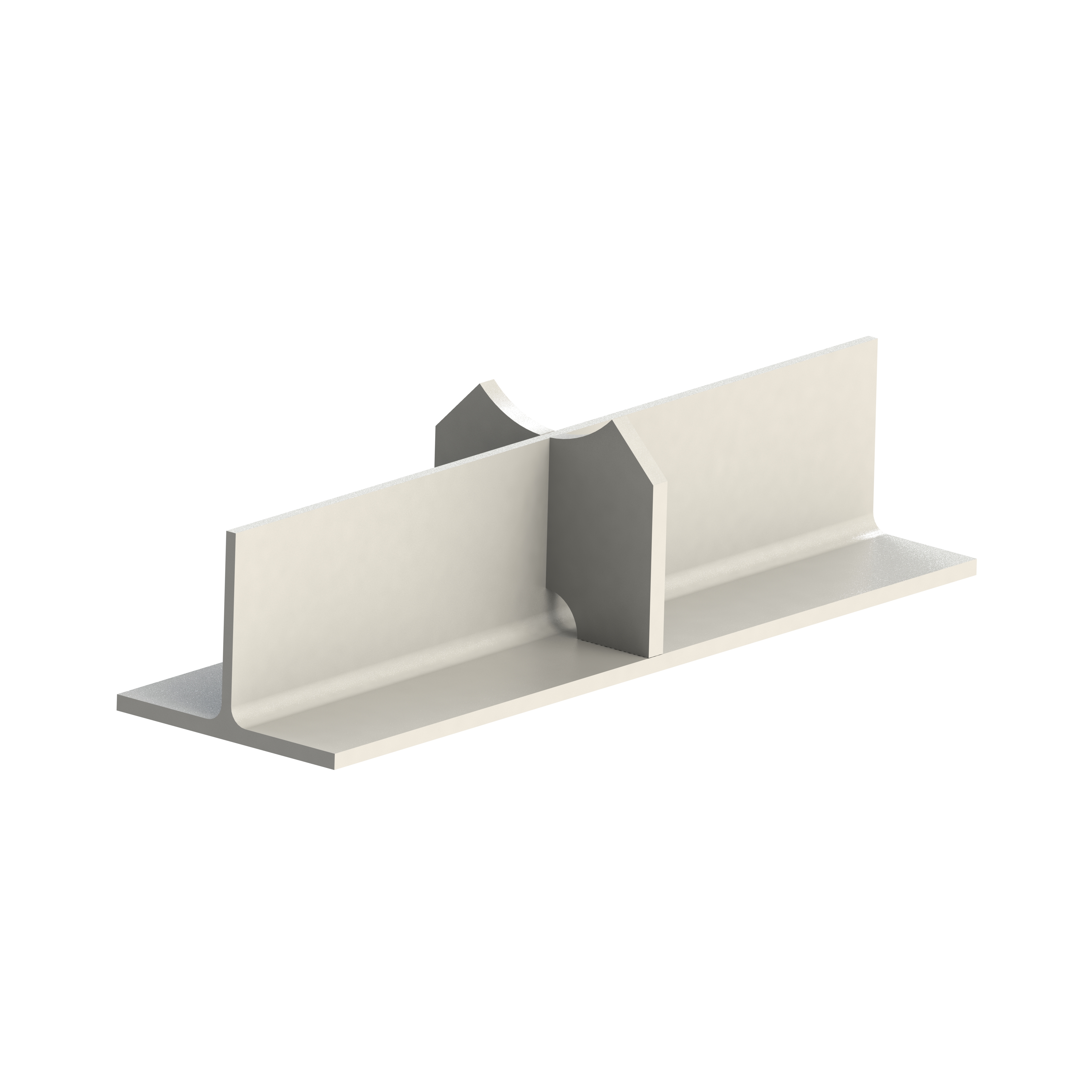

BG517

BG517COMPACT PIPE SHOE

BG400

BG400CLAMPED HOT PIPE SHOE

BG156

BG156INSULATED PIPE SHOE

BG157

BG157INSULATED PIPE SHOE

BG510

BG510STANDARD WELDED PIPE SHOE

BG518

BG518COMPACT WELDED PIPE SHOE

BG555

BG555STANDARD LINE STOPS

BG560

BG560STANDARD PIPE GUIDES

BG570

BG570STANDARD SHOE GUIDES

BG580

BG580STANDARD SHOE GUIDES

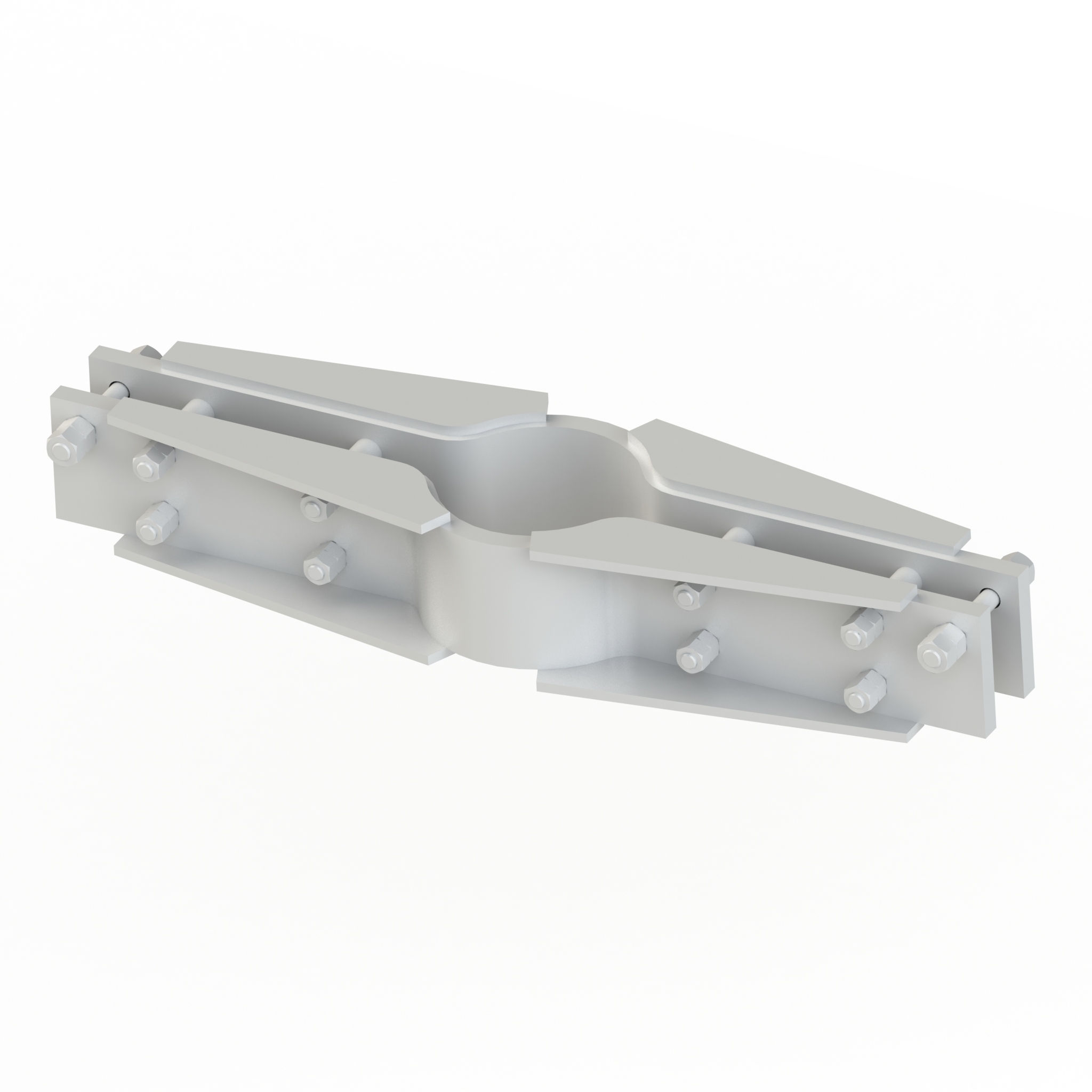

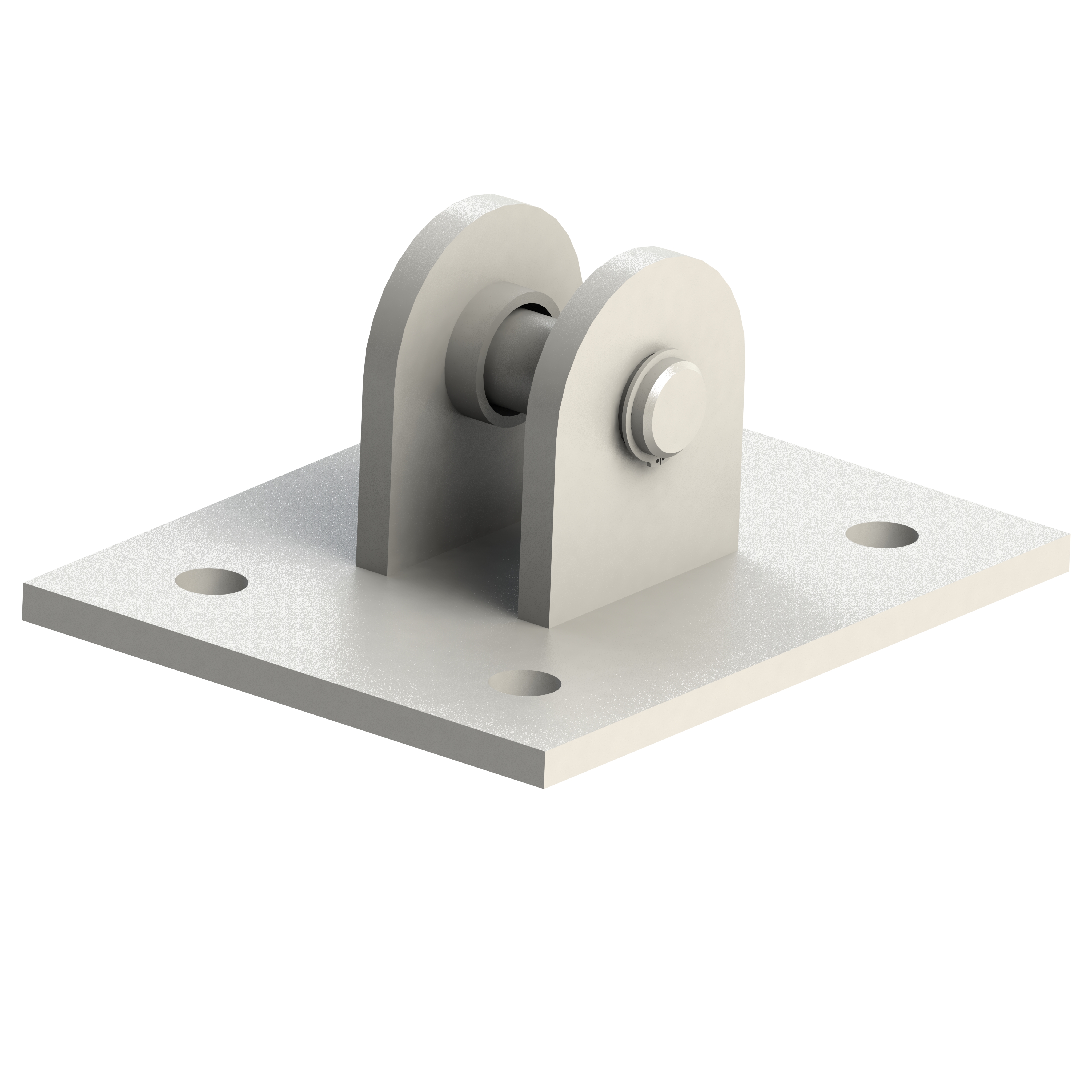

BG315

BG315END ATTACHMENT FOR HYDRAULIC SNUBBERS

BG355

BG355END ATTACHMENT FOR RIGID STRUT & SWAY BRACE

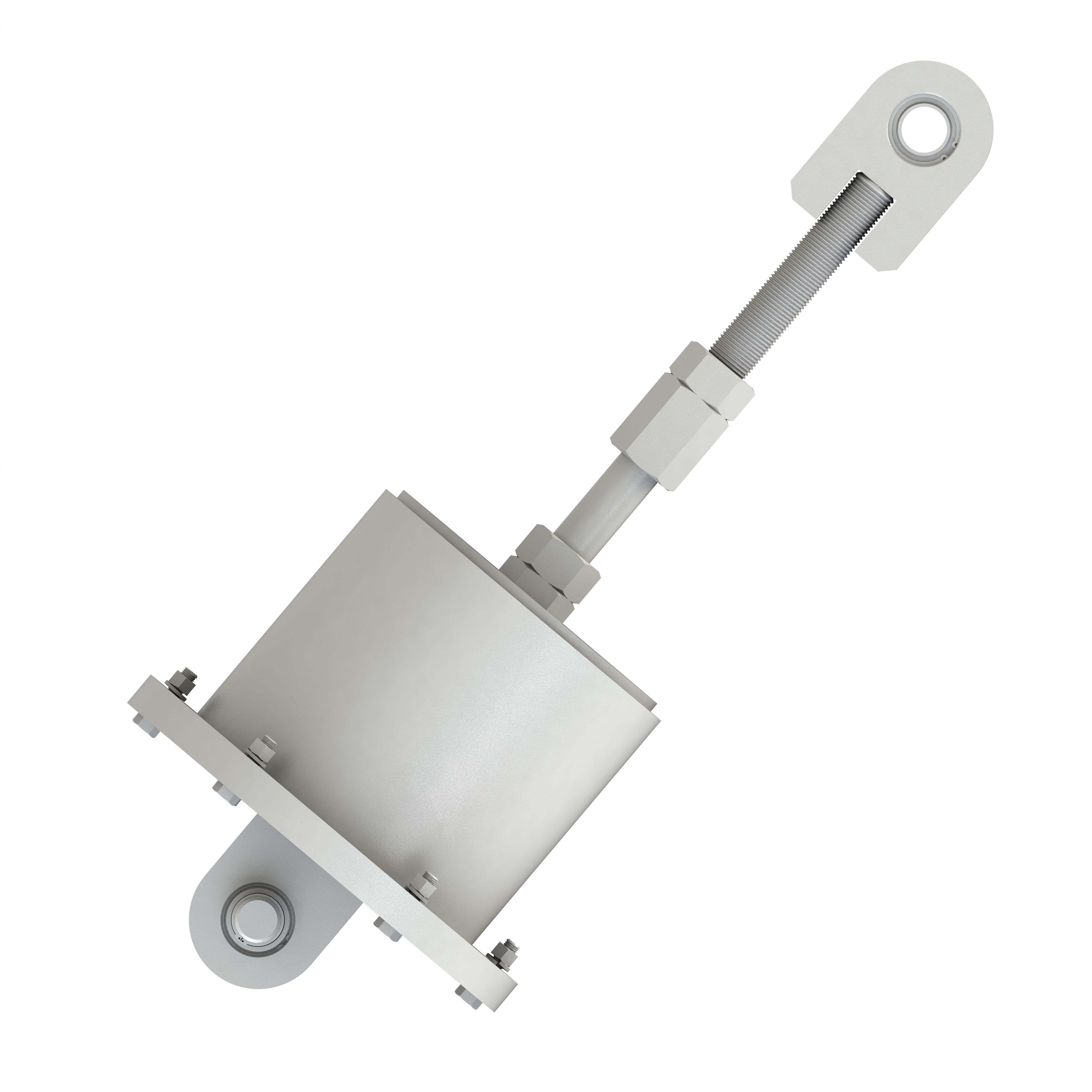

BG310

BG310HYDRAULIC SNUBBERS (SHOCK ARRESTORS)

BG321

BG321PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG322

BG322PIPE CLAMP FOR HYDRAULIC SNUBBER – HIGH TEMPERATURE

BG320

BG320PIPE CLAMP FOR HYDRAULIC SNUBBER – LOW TEMPERATURE

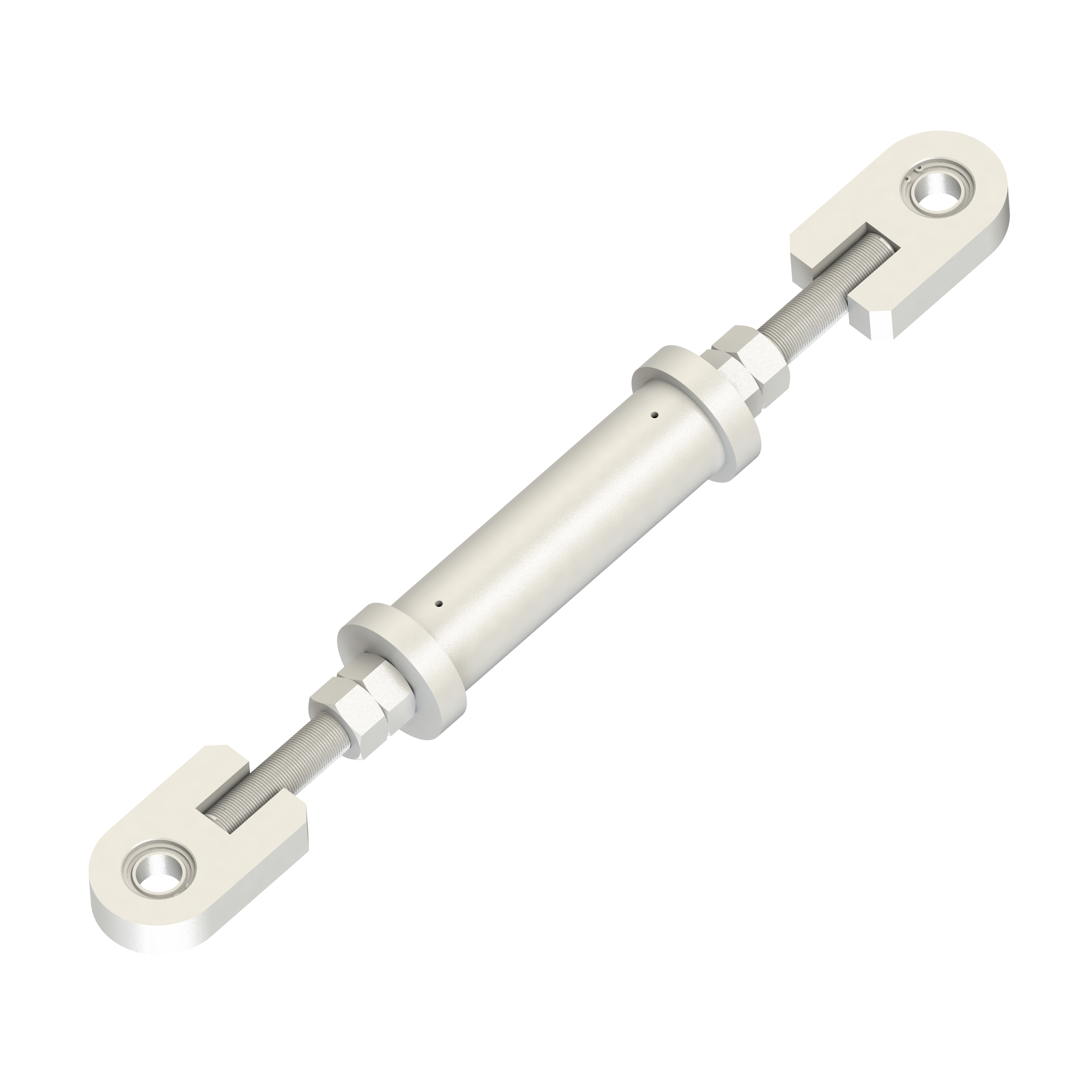

BG350

BG350RIGID STRUTS

BG340

BG340SWAY BRACE

#691028

#691028All Stainless Steel Gauge Adapter #691028

#520XL

#520XLAll Stainless Steel Gauge Adapter #520XL

#691023

#691023Brass Gauge Adapter #691023

#500BSP

#500BSPBrass Gauge Adapter #500BSP

#691024

#691024Brass Gauge Adapter #691024

#500XLBSP

#500XLBSPBrass Gauge Adapter #500XLBSP

691026

691026Brass Gauge Adapter #691026

#691027

#691027Brass Gauge Adapter #691027

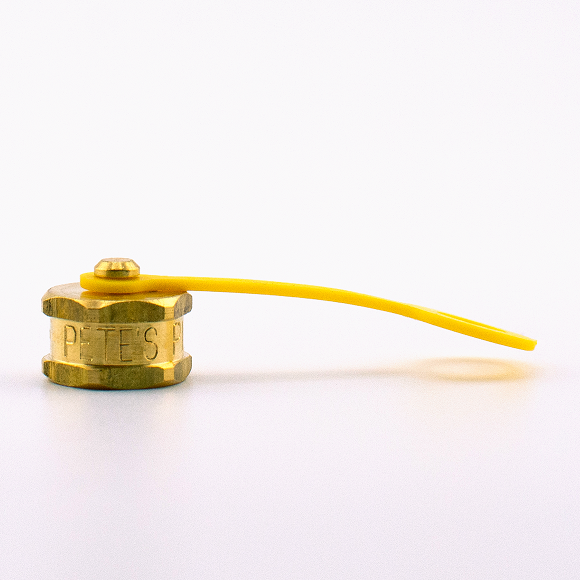

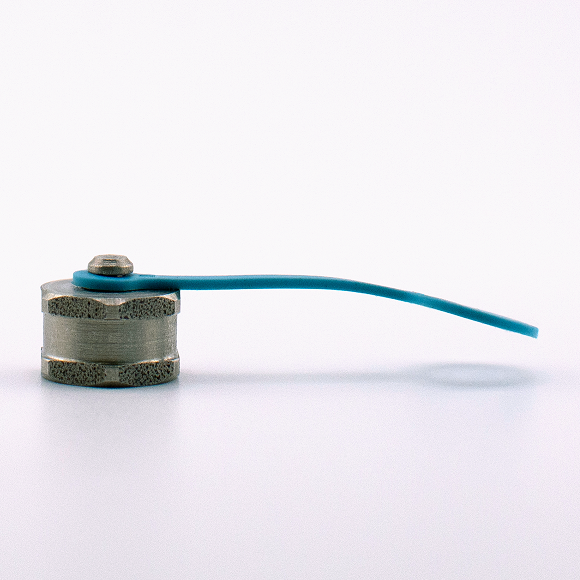

#104-1BS

#104-1BSCap Assembly #104-1BS

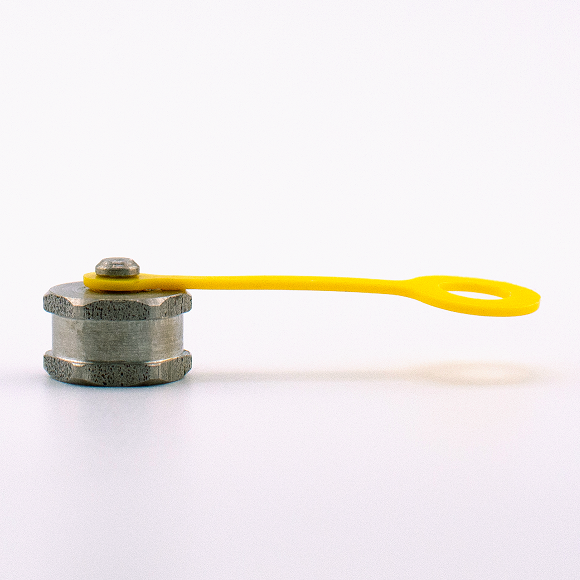

#104-1YS

#104-1YSCap Assembly #104-1YS

#104-2BS

#104-2BSCap Assembly #104-2BS

#104-2YS

#104-2YSCap Assembly #104-2YS

#691003

#691003Pete's Plug #691003

#691002

#691002Pete's Plug #691002

#691010

#691010Pete's Plug #691010

#691001

#691001Pete's Plug #691001

#691000

#691000Pete's Plug #691000

#691017

#691017Pete's Plug #691017

#12510

#12510Pete's Plug #12510

691020

691020Pete's Plug #691020

#691008

#691008Pete's Plug #691008

#691005

#691005Pete's Plug #691005

#691007

#691007Pete's Plug #691007

#691004

#691004Pete's Plug #691004

#572

#572Pete's Plug #572

#691019

#691019Pete's Plug #691019

#691018

#691018Pete's Plug #691018

#760

#760Pete's Plug #760

#691016

#691016Pete's Plug #691016

#691022

#691022Pete's Plug #691022

#691021

#691021Pete's Plug #691021

#691014

#691014Pete’s Plug #691014

#691013

#691013Pete’s Plug #691013

#562

#562Pete’s Plug #562

#691012

#691012Pete’s Plug #691012

#691011

#691011Pete’s Plug #691011

#750XL

#750XLPete’s Plug #750XL

#691015

#691015Pete’s Plug #691015

#691029

#691029Pressure & Temperature Test Kit 0-100psi

#691030

#691030Pressure & Temperature Test Kit 0-100psi for XL

#1500-5

#1500-5Pressure Gauge 0-100 PSI BSP Stem

#1500-4

#1500-4Pressure Gauge 0-100 PSI NPT Stem

#606

#606Thermometer -58°F to 550°F

-

-

-

- About

- Resources

- Contact

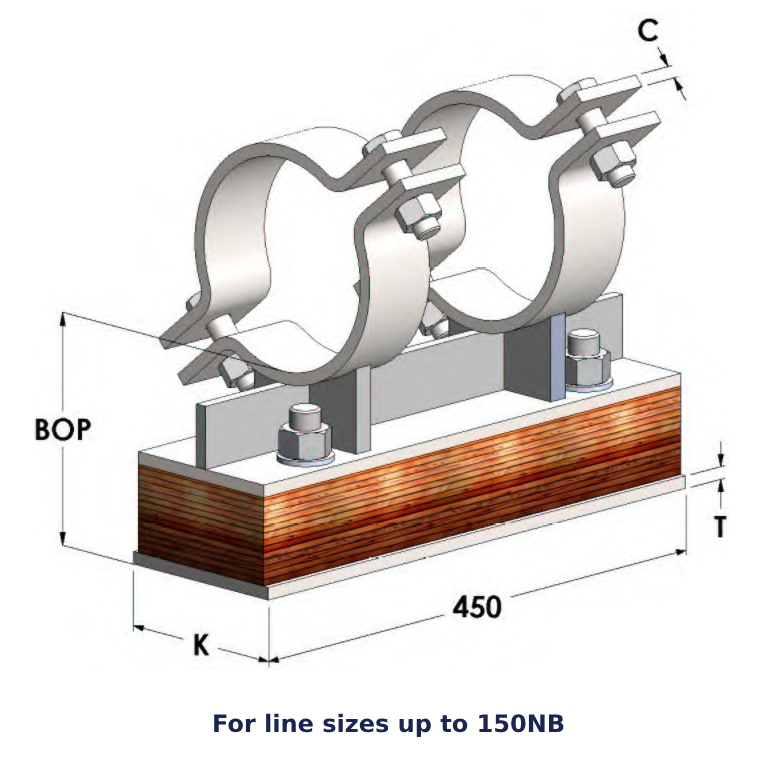

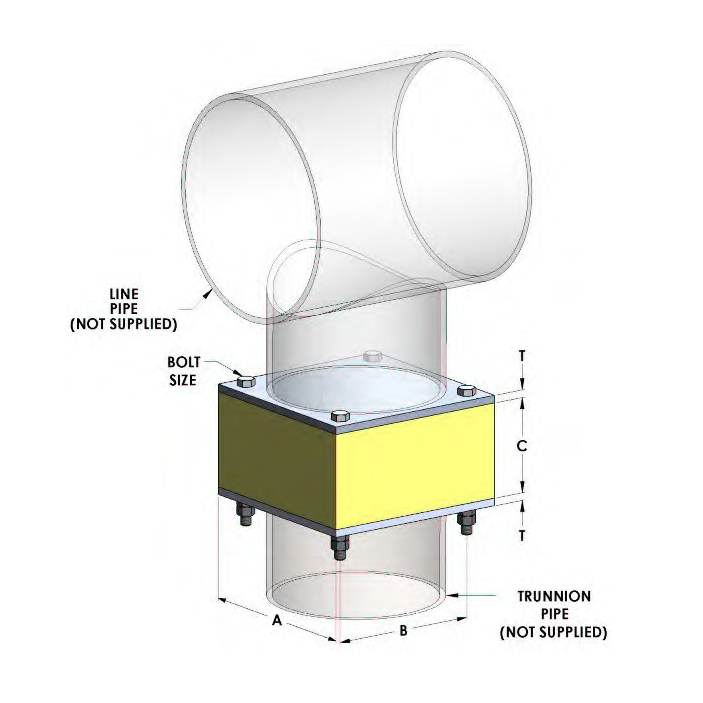

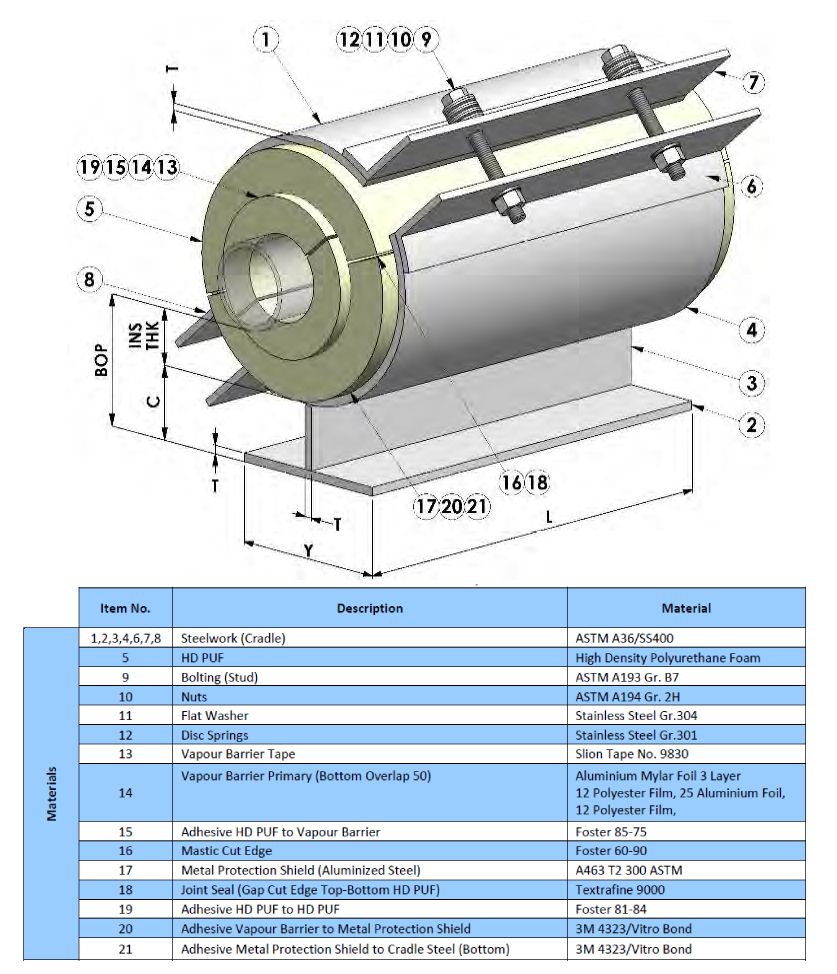

HD PUF CRYOGENIC PIPE SHOE BG600-603

(High Density Polyurethane Foam)

All Binder HD PUF cradles are manufactured from “NON-CFC” polyurethanes which are classified as self-extinguishing with a 90% retention of weight when tested in accordance with BS4735 and ASTM D-3014, respectively.

| Material | Specification | ||

|---|---|---|---|

| Surface Finish | Steelwork | ASTM A123 | HDG |

| Nuts & Bolts | ASTM A153 | HDG | |

| Washers & Disc Springs | Plain | ||

BG600

- The BG600 standard HD PUF Shoe is fitted with Disc Spring Washers on each bolt which ensures that the cradle is adequately clamped even after shrinkage has occurred due to the cryogenic operating temperature of the supported pipe.

- The clamping force is calculated so that the cradle will not rotate or slip axially on the pipe as the base experiences frictional resistance when the shoe is free to slide (un-guided) on the support structure.

- The frictional resistance is a result of the Vertical Design Load of the pipe and the shoe's Self Weight.

- A PTFE Slide Plate is recommended for larger diameter supports to reduce the sliding resistance and hence the clamping force required to prevent rotation.

- This design is applicable to 100NB pipe and greater sizes.

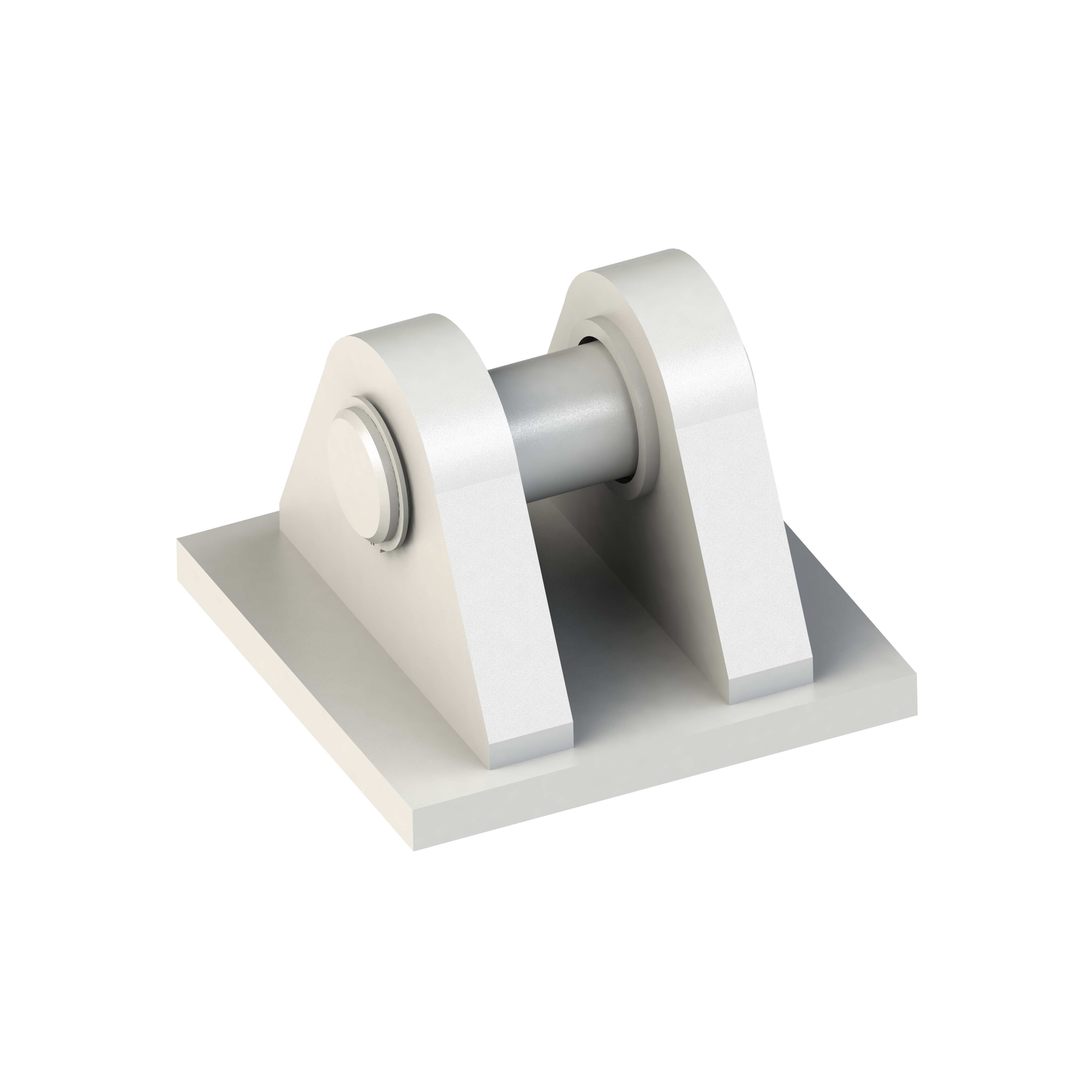

BG601

- The BG601 HD PUF Shoe is similar to the BG600 except it has an extra base attached to the top cradle to prevent the pipe lifting up during operation.

- For small up-lift forces, the BG600 can be used instead with hold-downs acting at the shoe base; however, this may result in higher clamping forces to prevent rotational slippage and will require calculations to be conducted as needed.

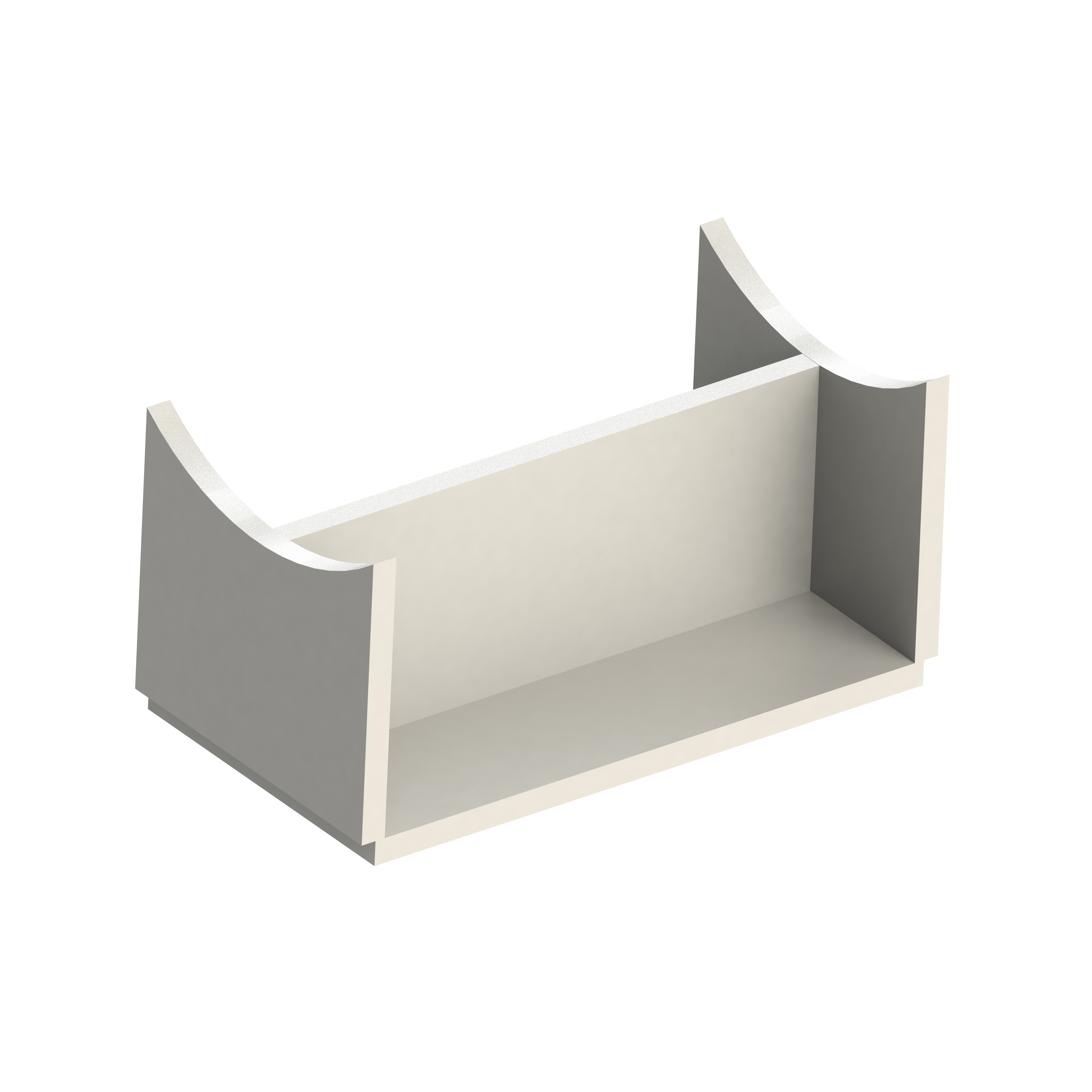

BG602

- The BG602 HD PUF Shoe is similar to the BG600 except it has guide bases attached to each side to resist large lateral forces.

- The effect of the guide bases mounted at the pipe centre line level is such that the shoe can manage large lateral loading without the need for high clamping forces to resist slippage.

- For small lateral forces, the BG600 can be used instead with guides acting at the shoe base; however, this will result in higher clamping forces to prevent rotational slippage and will require calculations to be conducted as needed.

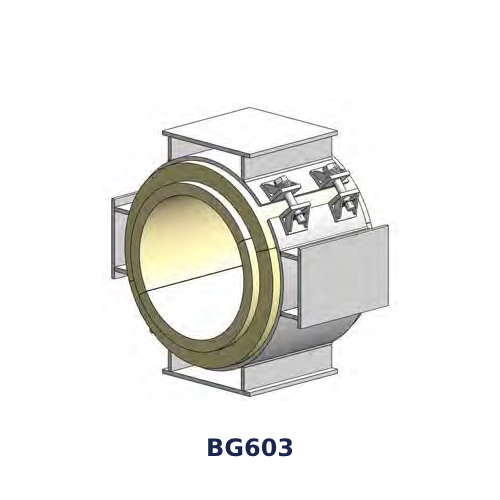

BG603

- The BG603 HD PUF Shoe has both the upper base of the BG601 and the guide bases of the BG602 to resist large up-lift and lateral forces.

- As with the BG602, effect of the guide bases mounted at the pipe centre line level is such that the shoe can manage large lateral loading without the need for high clamping forces to resist slipping.

- For small lateral and up-lift forces, the BG600 can be used with hold-down guides acting at the shoe base; however, this will result in higher clamping forces to prevent rotational slippage and will require calculations to be conducted as needed.

General Notes

- Total Insulation thickness is determined by the required operating temperature. Please refer to the insulation thickness v operating temperature table.

- Disc springs and bolting arrangements are calculated using design loads to prevent axial and rotational slippage. Bolting torques for installation are provided.

- Please provide vertical and lateral design loads if they exceed the design loads shown in design data table.

- Insulation is available in the following colour coded densities of 160, 240 and 320kg/m3 dependant on load requirements.

- Please contact Binder Group for pipe shoes requiring lateral, vertical or axial restraint.

- Standard batch traceability, complete with type 2.2 material certificates

- Pipe Shoes are welded to AWS D1.1 pre-qualified procedures

- BG550 type Teflon slide plates recommended for supports size 24” (600NB) and above. These are best ordered with the shoe.

- Alternative corrosion protection finishes available on request.

PRODUCT DATA